Automation is a time lapse - KW Solution

KW Solution

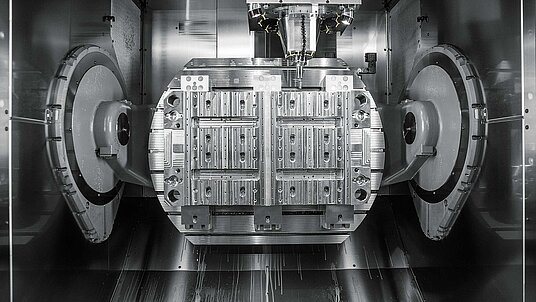

Tool and Mould Making

KW Solution has progressively evolved from a tool and mould maker into a subcontractor for individual parts and small series. The company relies on automated processes and the RS 2 robot system from HERMLE to efficiently manage high-mix, low-volume requirements.

It’s in his DNA

Trissler & Kielkopf GmbH

Contract Manufacturing

"The absolutely perfect system for a small company like ours," says managing director Robin Dorau about his RS L robot system from HERMLE, featuring two integrated C 42 U machining centres. With 150 pallets, it enables 24/7 production – from batch size 1. This is the only way for subcontractor Trissler & Kielkopf to secure its future and continue evolving.

From tradition to innovation- Viavorm

Viavorm

Contract Manufacturing

The Belgian precision specialist Viavorm is taking the next step: By operating the first RS 1 robot system from HERMLE in Belgium, the company is embracing intelligent automation – for even greater efficiency and precision in production. The company is transforming its production processes and turning night into day.

Long spindle runtimes despite single-shift operation

Chr. Held GmbH & Co. KG

Contract Manufacturing

Trading in industrial yarns, high-end bicycles and precision parts – Chr. Held GmbH & Co. KG has a diverse portfolio. Since 2023, the subcontractor has been prioritising automation: Together with the RS 05-2 robot system, the C 250 U from HERMLE turns night into day. The result: High efficiency through smart automation.

Going the extra mile - Diebold

Helmut Diebold GmbH & Co.

Tool Technology

Maximum precision in tool and spindle technology – Goldring tool holding fixtures are a prime example of this. Helmut Diebold GmbH & Co. manufactures high-end accessories for CNC machining. The company uses automated processes, for example the combination of a HERMLE C 42 U five-axis machining centre and the RS 2 robot system.

Smith & Co. opted exclusively for HERMLE machining centres

Smith & Co.

Defense, Medical, Commericial

Smith & Co. chose to invest heavily in its people, processes and solely HERMLE equipment, garnering lights-out manufacturing work.

Diversify, Expand Into New Industries

MetalQuest Unlimited

Aerospace, Space, and Medical

MetalQuest Unlimited has been delivering contract manufacturing services for years. Always looking to stay ahead of the technological curve, MetalQuest set its sights on acquiring a 5-axis machine.

With the capability to machine parts on their new HERMLE C 250 with RS 05-2 automation, MetalQuest expanded into new industries, including aerospace, space, and medical. This move allowed the company to diversify and leverage the systems they already had in place.

HERMLE machines and services have become an integral part of our manufacturing processes

Motor Classic Hungary

Automotive industry

Motor-Classic Hungary was founded in 1995 and has grown into one of Europe’s premier classic car restoration workshop complexes.

Motor-Classic, headquartered in Tatabánya, operates on over 8,000 square meters of industrial space, employing more than 100 highly skilled professionals. Reflecting its consistent growth, the company recently expanded with a 1,500-square-meter production facility and is set to complete an additional 1,500-square-meter warehouse.

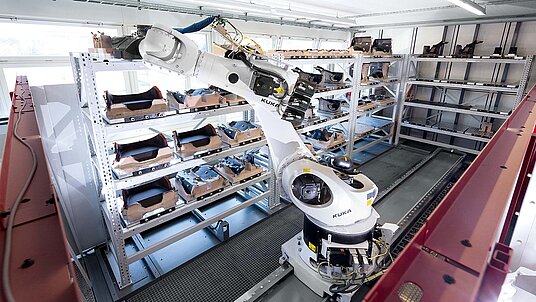

Standardised management for high flexibility

Euler Feinmechanik

Contract manufacturing

Euler Feinmechanik machines roughly 3,500 different items for its customers – with batch sizes ranging from 1 to 5,000. To handle this level of variety, the subcontractor relies on automated HERMLE machining centres. The standardisation of the systems enables the company to respond flexibly to all enquiries.

Manufacturing more flexibly with clamping components

Condor Group

Contract manufacturing

Milling and automation from a single source – this was the impetus of the Condor Group for choosing the solution from HERMLE. The RS 1 robot system supplies two C 32 U 5-axis machining centres with workpieces, turning night into day. To further maximise the effectiveness of the system, the contract manufacturer developed its own die system.

Partners in precision and perfection

MBM-Schnaittenbach

Contract manufacturing

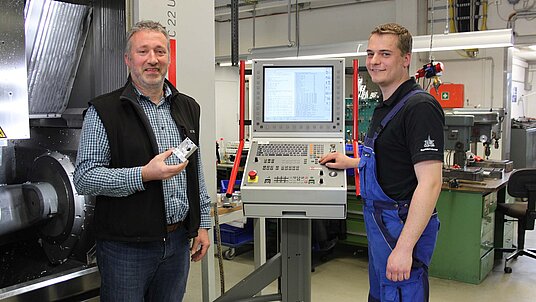

Once HERMLE – always HERMLE. Wolfgang Müller capitalises on CNC machining centres from Gosheim in his small family operation MBM-Schnaittenbach. The second C 12 U has just been added, to significantly increase capacity. The next step will be getting started in automation.

The new one's name is Alberta

P&S machine construction

Contract manufacturing

Lengthening spindle runtimes and making use of night-time hours – P&S Maschinenbau is capitalising on automation with the new HERMLE C 32 U HS flex. The company will use it to produce workpieces for its own machines for cutting and grinding, but will also manufacture high-precision special components for customer orders.

Deeply rooted

Biersack Group

Contract manufacturing

Reliable automation, precise and contamination-free manufacturing – the Biersack Group had specific requirements for its new machining centre. The contract manufacturer was absolutely impressed by the C 32 U HS flex from HERMLE, not only by its perfect cutting accuracy, but also because it carries out all orders fully automatically.

User-friendly 5-axis technology exceeds manufacturer’s expectations

M&L Precision Machining

Medical Technology

Since 1971 precision manufacturer of CNC components, M&L Precision Machining Inc, has been crafting products for the Medical Devices, Aerospace, Defense, and Technology industries. Always delivering on promises to customers and employees, M&L Precision knew the quality of HERLME machines and decided to invest in the best.

Wisconsin ultra-high-precision shop only reinvests in the best machinery.

Owens Industries

Aerospace

In today’s world of manufacturing, establishing a niche and maximizing processes are invaluable advantages. Having the right equipment to do so, that’s a challenge Owens Industries tackled head on – most recently purchasing two additional HERMLE Performance Line C 400 milling machines.

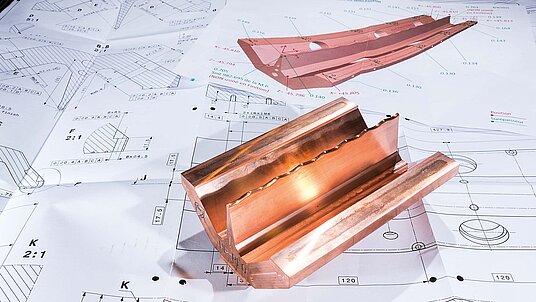

The HERMLE machines created new possibilities and advantages

Eifel Mold & Engineering

Plastic Engineering

HERMLE Machines and Services Pull Michigan Mold Builder into Future of Manufacturing.

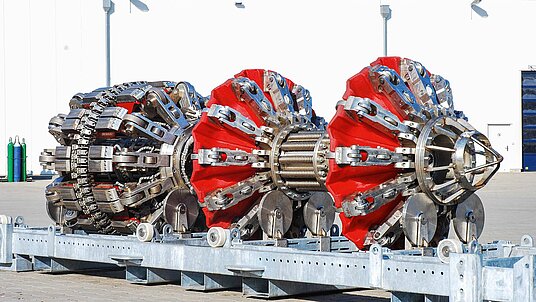

5-axis technology for etching, washing, drying

Ramgraber GmbH

Supplier industry

According to World Semiconductor Trade Statistics (WSTS), the European market was projected to experience growth of 6.3% in 2023. This fact also has a direct impact on suppliers like Ramgraber: Microchip manufacturers utilise its equipment to etch, structure, strip, plate, wash and dry their wafers – often based on silicon, silicon carbide, gallium arsenide, glass or ceramics. The company places a significant emphasis on vertical integration, a principle to which the HERMLE C 400 U also contributes.

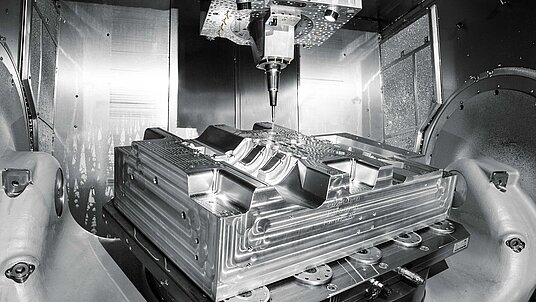

Success through machine clones

Precupa GmbH

Tool technology

Precupa combines high-precision tool making with plastic injection moulding and develops injection moulding solutions for the world of tomorrow at its technical centre. One of the core competences in production is milling. This is where the precision tool maker relies on HERMLE, making full use of its entire Performance Line.