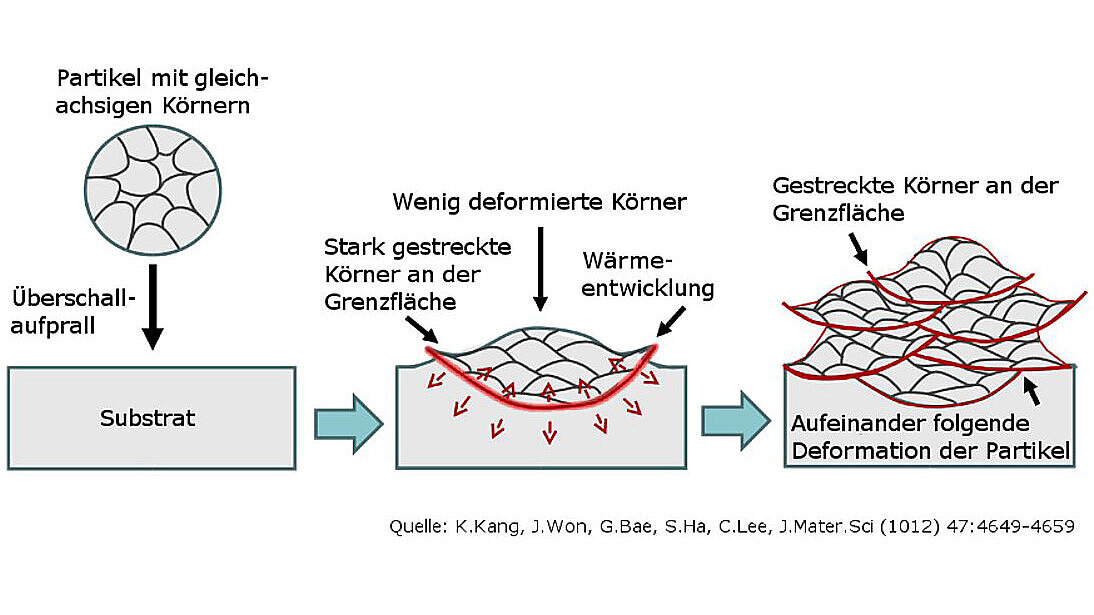

Basic raw material metal powder

Metal powder is the basic raw material for additive manufacturing using the HERMLE MPA process. The physical properties of the applied metal layers and the material transitions must meet the high mechanical and thermal requirements of the operational environment of the component being manufactured. Optimum coordination of the process parameters is therefore essential for each metal powder used. The properties of the resulting microstructure are determined through extensive series of tests. In addition to tensile and compression tests, information about particle and layer adhesion, porosity and any inclusions is derived from the examination of grindings under a light microscope.