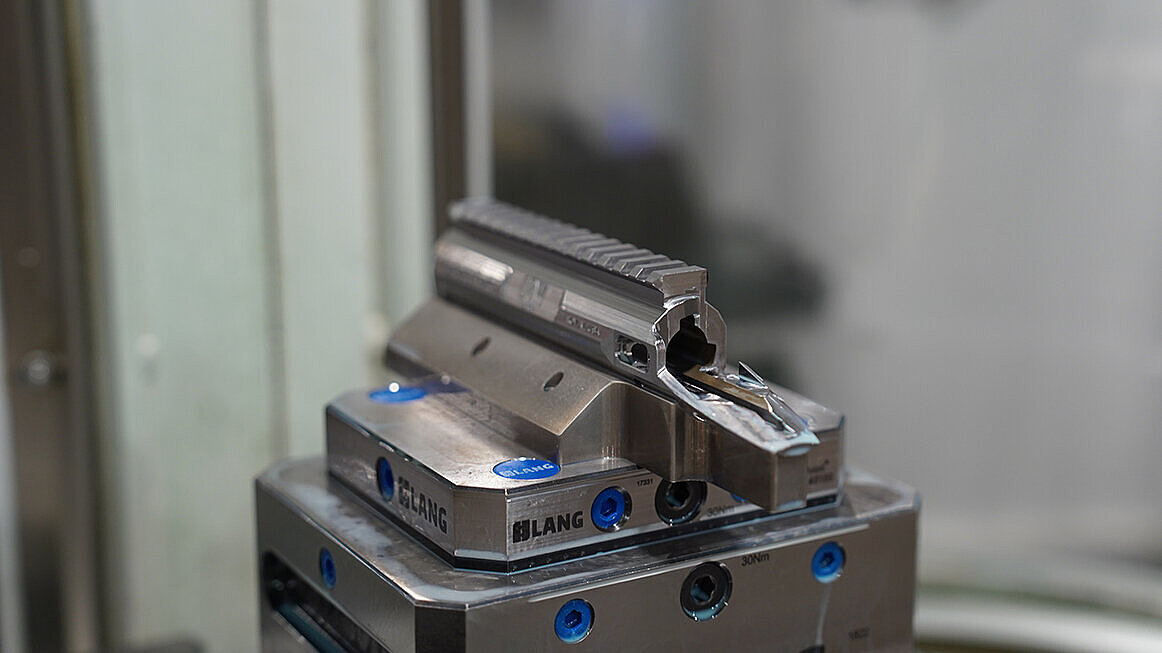

Innovation using 5-axis technology for firearms production

Founded during the Great Recession of 2008, Detroit Gun Works evolved from a small contract manufacturer to a highly efficient producer of bolt-action and barreled rifles. They elevated their production process by utilizing advanced machinery like the HERMLE C 400 with HS flex automation.

Brothers Arnot (President) and Matt (Vice President) Heller are fourth-generation machinists who wanted to elevate the company’s strong foundation.

“We were looking for ways to diversify our business, and we always wanted to be in aerospace,” said Arnot. “We identified the firearms business as a lower-risk option, but precision was still important, so that’s why we founded DGW.”

During the Great Depression, their grandfather and great-grandfather founded a company in Detroit, which evolved into Central Screw Products. Arnot and Matt decided to diversify their product portfolio, launching DGW with a new vision. They expanded into suppressor work and secured government contracts, including designing a new weapon platform during the COVID-19 pandemic.

“Not only could we go to work, we had to go to work,” Arnot recalls.

To meet growing demands, they invested in advanced machinery, turning to HERMLE for a solution.

Arnot describes their initial situation:

“Once that program went away, we had this machine tool that we went to fill with our old methods (contract manufacturing), which was not using the machine to its full abilities. It was like using a Ferrari as a lawn mower.”

Realizing the potential of their HERMLE machine, DGW fully embraced 5-axis machining, despite a notable learning curve.

“When we bought our HERMLE, we did not know how to run 5-axis. We were good machinists, but HERMLE and our distributor promised us, ‘This is who you need to buy from to learn how to run 5-axis,’” says Arnot. “This is the first promise that has been kept for us in continuing education. We’ve had fantastic support from HERMLE.”

Adam Yednock, Accounting Manager at DGW, shares the excitement surrounding the HS flex automation. They were able to integrate automation into their processes so seamlessly that, as the team joked, they wanted to make it so easy “an accountant could run it” – and he did.

The C 400 and HS flex automation allows DGW to run production overnight, maximizing efficiency and reducing employee fatigue. With minimal need for oversight, the machine enables DGW to produce high-quality parts while minimizing downtime.

“The employees don’t need to work so hard. They are happier and not so tired at the end of the day,” said Yednock.

HERMLE’s exceptional service empowered them to push the machine limits, constantly exploring new ways to improve their processes and expand their capabilities. The seamless integration of automation allowed DGW to be more creative and efficient, increasing the quality and volume of their production.

Matt praised the flexibility and low maintenance of their HERMLE C 400.

“There has been no need to service the machine. It is as accurate as it was the day we bought it,” said Matt.

With the ability to run continuously, DGW scaled its operations and expanded product offerings without sacrificing precision. Matt notes how the HERMLE single-source OEM solution alleviates the need to learn and integrate multiple systems.

Looking ahead, DGW is focused on becoming the leading configurable rifle builder in the market. Arnot and Matt remain committed to refining their production processes and improving their workflow, all with the support of HERMLE.

“That’s really where our next step is, to promote our brand and promote our products, while maintaining continuous process improvement,” says Arnot.

With their advanced technology and drive to deliver quality, DGW is looking to lead the market, producing customizable, durable, and highly accurate rifles. The future is bright as they continue to push the boundaries of what’s possible in the firearms industry.