C 60 U | Meissner AG | Mould and tool making

As a leading international provider of complete services in mould and tool making, medium-size company Meissner AG uses three Hermle C 60 U 5-axis CNC high performance machining centres to ensure ROI (Return on Investment) for its customer base.

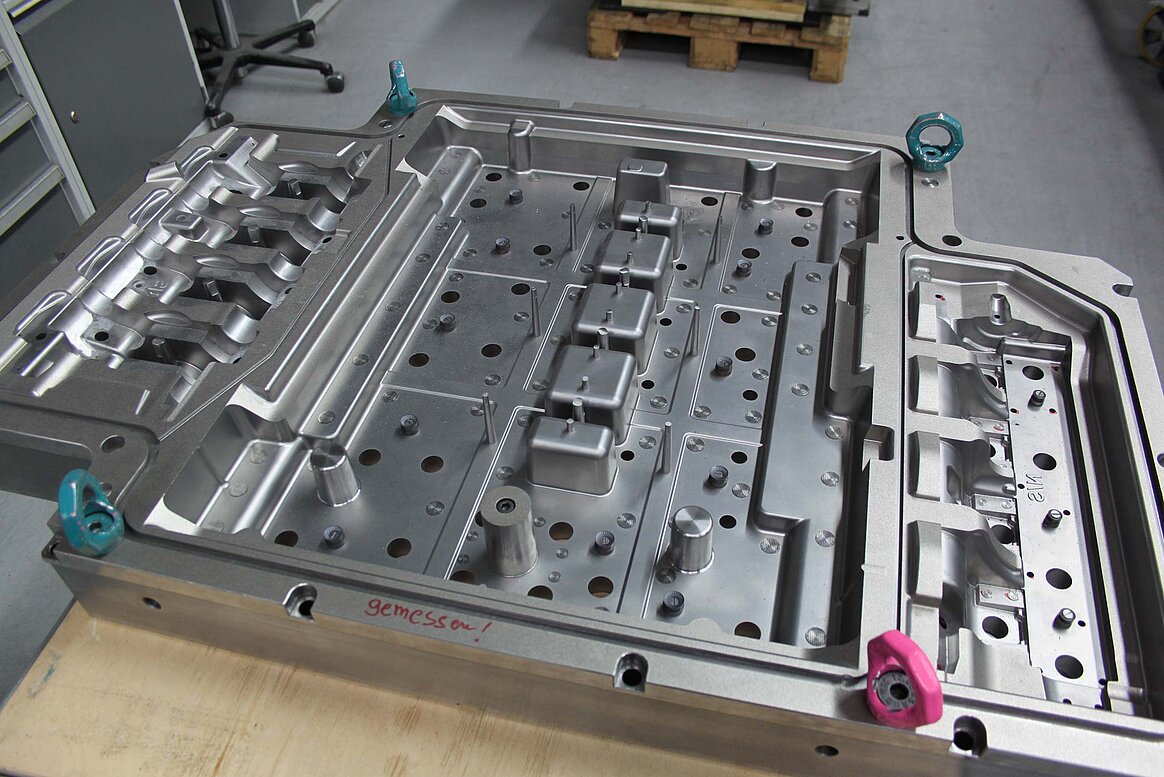

"Precision and performance for the world market" – That's not just a slogan at Meissner AG in Biedenkopf-Wallau in the German state of Hesse, it's emphatically lived. A major reason for that is a construct which is unfortunately not widely known yet in our part of the world: the employee owned company, where a majority of the company's stock is owned by the employees. This has many practical advantages, such as employees having a sense of responsibility for their "own" company, which in turn encourages every employee to act responsibly and in the best business interests of the company. The model and to a large extent the product concept of the company as well have stood the test of time to this day and their expression may be found in extraordinary performance and high quality in products and services for high end mould and tool making. The family owned company founded in 1922 was transformed into an employee-owned stock company, Meissner AG in 1997. This marks the beginning of a success story that continues to this day. The Meissner AG location in Biedenkopf-Wallau counts over 300 employees, with about 100 additional employees at the Chinese location in Kunshan. Focussed on high-end complete technical solutions in three segments – foundry tools, blow moulding and tools for vehicle linings – the company divides the process chain for its range of services into Product Development & Engineering, Rapid Prototyping, Mould and Tool making, Quality Control, Running in Tools and finally Service. Most of the tool systems go into the automotive sector, where the customer base includes many manufacturers and their technology partners or suppliers.

The challenge: Manufacturing larger tools economically

To be able to meet the high standards of globally operating customers flexibly at any time, the company uses the latest technology and processes and trained specialists, many of them trained in-house. Reinhard Hackler Director of Mechanical Manufacturing, noted at this point: "We are strictly process and performance-oriented. What the fifty-some development and design specialists create in the Engineering department is immediately and efficiently implemented into tool systems with special attention to quality by over 200 manufacturing specialists. To do this we have access to an ultra-modern machine park of CNC machining centres, CNC milling machines for large parts and also CNC turning machines. Milling takes the lion's share today with about 90% of all our work. We also see a strong trend towards larger moulds and tools due to progressive efforts for more efficiency in terms of material and energy plus increasing functional integration or power density in automotive subassemblies." The practical effect of this is that the moulds and tools consist of larger base units and larger parts, which creates a need for larger machines. It is also important to present moulds and tools to customers so they are economically feasible based on the Meissner ROI philosophy. Because of all this, investing in larger CNC machines goes hand-in-hand with promoting 5-axis technology for efficient complete manufacturing. Optimally equipped with comprehensive experience from many years in mechanical machining, the company had taken the plunge into 5-axis technology some time ago. Now the next step followed in the form of a C 42 U 5-axis CNC high performance machining centre from Maschinenfabrik Berthold Hermle AG, D-78559 Gosheim. That made 5-axis/5-sided complete machining possible and especially simultaneous machining, first on smaller and medium-sized tool parts. After just a short period of familiarisation and optimisation with the C 42 U machining centre, the decision was made to automate manufacturing of large parts by using larger 5-axis machines, and to invest in 5-axis machining centres for dynamic complete machining of large parts.

Highly automated contour, simultaneous and complete milling

Markus Hunger commented: "After a brief evaluation it was clear to us that we would use the new type C 60 U large parts machining centres from Hermle AG because they seem to be ideal for our intended purpose of complete and simultaneous machining. We now prefer to use three C 60 U machines for contouring and simultaneous milling at a high level of automation. Based on demonstrated performance we successively bring complex tools or parts one by one to these 5-axis machining centres, which explains the high need for capacity for three identical machines of this type. We work in 1 to 3 shifts here as needed to ensure minimum operator control of systems so that we can make optimum use of the machines' performance capacity." The C 60 U 5-axis CNC high performance machining centres are ideal for machining assignments at Meissner AG with their working range of X =1200, Y = 1300 and Z = 900 mm and the allowable piece weight of up to 2500 kg in dynamic 5-axis/5-sided machining. The three C 60 U machining centres are nearly identically equipped with a main spindle running at max. speed 18000 rpm, HSK-A 63 tool holding fixture, tool magazine with 70 pockets, 80-bar internal coolant supply and the Heidenhain iTNC 530 HSCI control unit. There are differences in the NC swivelling rotary tables, as two machines are equipped with an NC swivelling rotary table (SRT) 900 mm in diameter while one machine has an SRT measuring 1350 x 1000 mm. This ensures great flexibility in application and usage with otherwise identical performance features. Of course it is also advantageous that the first Hermle C 42 U machining centre to be purchased as well as the three C 60 U machines that were needed later are all equipped with the same control technology. This makes it easier to work with the 5-axis machining centres and use them in a highly flexible manner for daily tasks, from programming for machine operation and process optimisation to user knowhow.