C 60 U | LANGER Mould making - Model making

From developing initial models and prototype tools to making moulds for large batch series of injection mould components – discover how the technology firm Langer Group has used the high-performance, 5-axis C 60 U CNC machining centre from Hermle to streamline its manufacturing capacities.

When model maker Anton Langer established his company roughly 40 years ago, the world of model, mould and tool making was very different than it is today. Cast and injection mould parts were gradually developed using models and moulds, a process that has remained the same in principle. However, over the past 40 years many new technologies have entered this world which not only enable simultaneous and thus faster work, but have also made some processes obsolete and allow customers to benefit from a faster time-to-market. No one knows this better than the current company Langer GmbH & Co. KG from Illmensee, D-88636, which, together with LARO NC-Technik GmbH, forms the Langer Group. The Group employs roughly 180 people (160 skilled staff and 20 trainees), of which 150 work for Langer GmbH & Co. KG and 30 for LARO NC-Technik GmbH. The products and services provided by Langer range from development and construction to sampling and mass production in the fields of model making/cubing technology, test tool construction, prototype mould construction, mould making for series production, composite/RTM up to injection mould parts for the automotive, medical technology, aerospace sectors. LARO, as a premier provider of machining services for Langer and other customers, focusses on the precision machining of large parts. As a technology company Langer boasts extensive and high-capacity production facilities to provide customers with models, samples, prototype moulds and production moulds as quickly and as flexibility as possible.

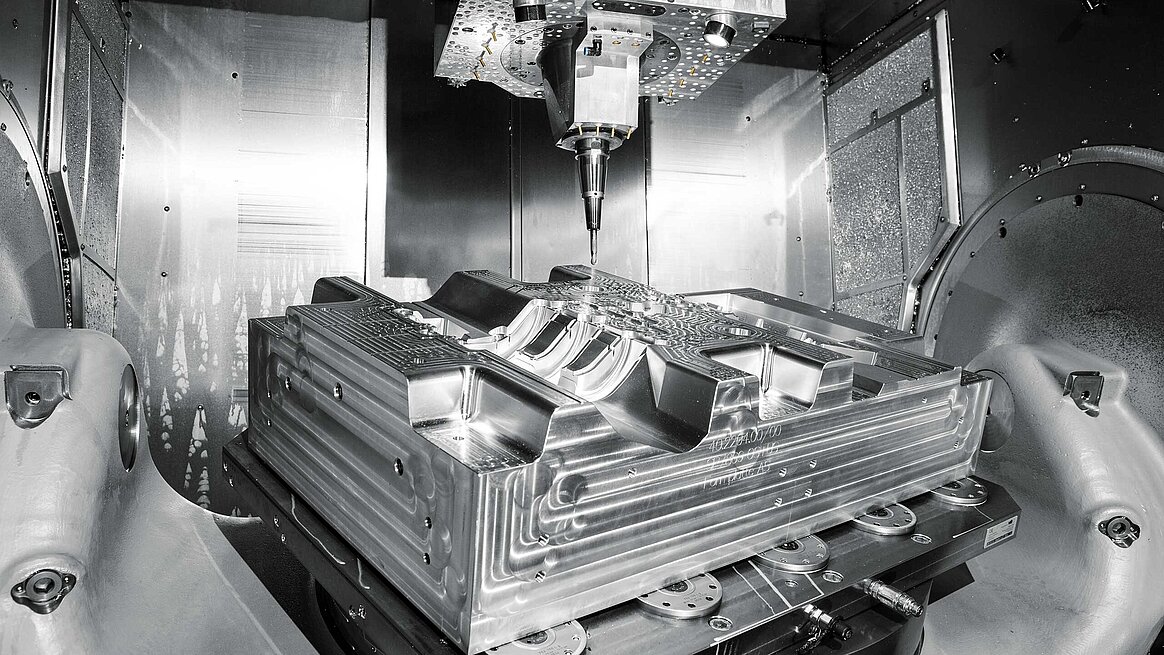

5-axis milling expertise for all tool elements and mould parts

Jörg Lehmann, team leader of NC production at Langer says: "In our independent department, thirteen highly qualified members of staff produce all the tool elements for mould making at ultra-modern CNC machining centres. This includes moulds and dies, mould plates, mould inserts, slides and production mould parts using tool steels up to hardnesses of 60 HRC. We additionally produce all the tool components for prototype moulds made of aluminium. A real challenge for us are the ever larger and, in terms of the conformal cooling systems, considerably more intricate injection mould tools. This is the reason why we need highly flexible and high-precision 5-axis systems with appropriate working ranges. A CAM system is absolutely essential for machine programming due to the complexity of the mould parts involved. We work in two shifts at the milling machines and plan the third shift unmanned." In order to cope with the expected increasing demands and the sheer volume of business, which required among other things a notable expansion of capacities, Langer decided in 2009, after an extensive evaluation and test phase, to invest in high-performance CNC machining centres from Maschinenfabrik Berthold Hermle AG in Gosheim, D-78559. The first machine was a C 40 V CNC machining centre (3-axis version) in order to carry out preparatory work more efficiently for 5-axis/5-sided complete/simultaneous machining. The excellent results achieved with the machine, its simple operation and the full technical advice and service provided, led to Langer purchasing a high-performance, 5-axis C 60 U CNC machining centre from Hermle in 2010. Two years later the company acquired a high-performance, 5-axis C 42 U CNC machining centre and in 2014 another high-performance, 5-axis C 60 U CNC machining centre.

(Almost) identical machining centre equipment of the highest standard

In order to fully utilise the learning, programming and operating experiences in a "synergistic" manner, all the Hermle machines in the NC department at Langer basically come with the same features and NC controls (Heidenhain iTNC 530). However, the last-mentioned C 60 U machining centre was fitted with a ZM 110 additional magazine, meaning this system now delivers 70 plus 110 = 180 tools using an HSK A63 holding fixture. Today, the two large high-performance, 5-axis C 60 U CNC machining centres form the backbone for the flexible and time-saving production of mould parts, as they, for example, enable the simultaneous mirror image machining of components (mould plates) for a complete tool. Jörg Lehmann explains: "The two Hermle C 60 U machining centres allow us to execute the complete machining of intricate workpieces, from roughing to finishing, in one setup. Depending on the complexity and size, we have cycle times of up to 125 hours, which was yet another reason to invest in a further C 60 U machining centre. Furthermore, at these machines we are able to drill holes up to 360 mm deep, without the need for a deep-hole boring machine and the tool handling, setup and programming this would entail." Thanks to the 900 mm NC rotary tables, maximum table loads of 2500 kg, the extensive and fully usable working ranges (X = 1200 x Y = 1300 x Z = 900 mm), and last, but not least, the main spindles designed for roughing and finishing with top speeds of 18000 rpm, the Hermle C 60 U machining centres find themselves doing the lion's share of the precision machining. In addition to this, the two machining centres represent a type of redundancy, as they deliver correspondingly high production rates and flexibility, which Jörg Lehmann puts at roughly 5,900 hours annually per machine based on the actual range and complexity of parts that require machining.