C 32 | C 400 | RS 2 | Heron CNC Technik GmbH | RS 2 robot plant with automated warehouse connection

Heron CNC Technik GmbH manufactures prototypes and series parts, mainly from aluminium. In order to enable unattended production despite the short run times involved, this Austrian company has combined an automated Hermle plant – two 5-axis milling centres and the RS 2 robot system – with the Servus autonomous robotic carrier system manufactured by its own affiliated company Servus Intralogistics. The result: an inter-system automation solution that fulfils high demands in terms of precision and quality.

Without a mask, but with SAFEDI flashing from his collar, Manuel Gmeiner shows what he is responsible for as the CEO of Heron CNC Technik GmbH. Ten 5-axis machining centres, all of them from Gosheim and manufactured by Maschinenfabrik Berthold Hermle AG. They share around 500 square metres of production space with the manufacturing departments of Robotunits GmbH and Servus Intralogistics GmbH. The assembly area for SAFEDI Distance Control GmbH is brand new. Within the space of 6 weeks, this company developed a small clip that registers close contacts and analyses infection chains – without any reference to sources of personal data. "If an infectious case is diagnosed, all those SAFEDIs are informed that have experienced close contact with the infected person according to the contacts diary. This ensures effective interruption of the infection chain, and we can keep the operation going," explains Gmeiner on the way through the daylit production hall.

Heron CNC Technik GmbH was founded in 1999 for the purpose of manufacturing parts both for internal use as well as for other companies. "We achieve over 50% of our turnover through external orders. This helps us to stay agile and in touch with the market," says Gmeiner. The remaining capacity is reserved for the other Heron subsidiaries.

Heron CNC Technik, Robotunits, Servus and SAFEDI are all rooted in the company Heron Sondermaschinenbau GmbH. The core business of this company, founded in Dornbirn by Christian Beer in 1988, was originally the development and construction of assembly-line robots. Six years later, the first of the subsidiaries was founded with the launch of the Robotunits automation kit. The metal cutting technology was reorganized as an independent unit in 1999. Since the establishment of Servus Intralogistics GmbH in 2005, the intelligent and autonomous Servus robotic carrier system has been taking the market by storm. Today, the parent company operates as a service provider to the four subsidiary companies, dealing with coaching and financial topics as well as human resources development and product development.

A concept for success: Quality and service

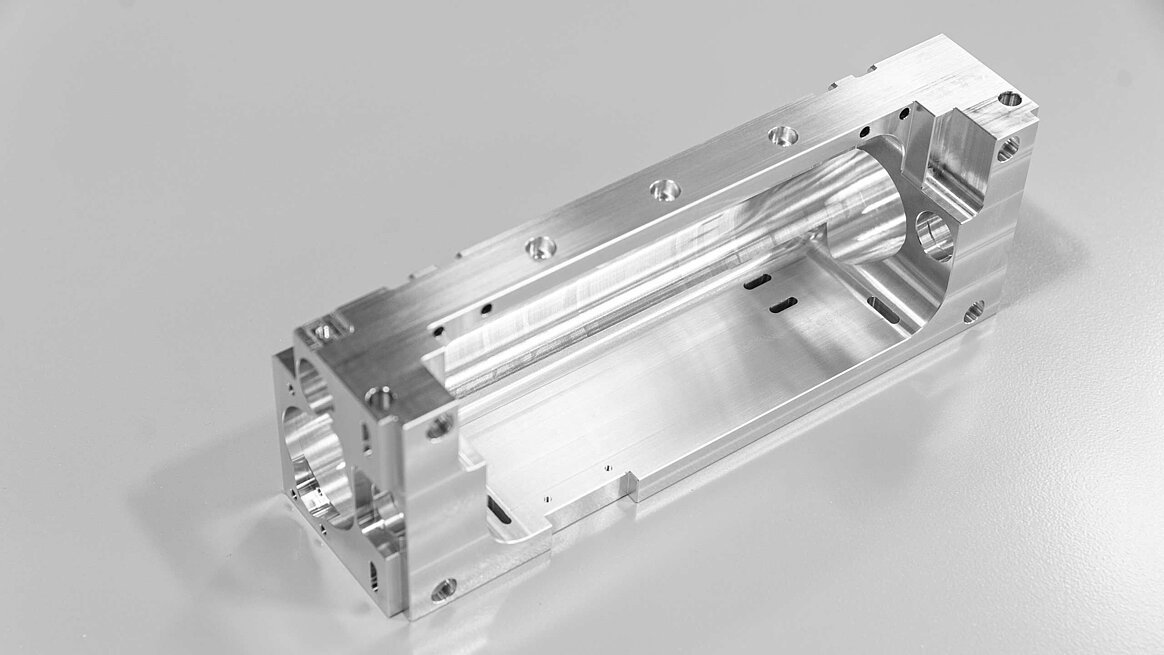

"We manufacture prototypes as well as series parts in batches ranging from 1 to 10,000 for machine manufacturers, medical technology firms as well as the semiconductor industry," explains the 29-year-old who started his career as a trainee at Heron CNC Technik and has been the subsidiary's CEO for the last 3 years. "For us, quality, precision and service have top priority, which puts us on the same wavelength as Hermle."

The first Hermle machining centre was acquired about 25 years ago. Since then, Heron has remained a loyal customer of the machine manufacturer from Gosheim, steadily increasing its pool of machines to today's total of ten 5-axis milling centres. "We mill exclusively on Hermle machines. Here we are convinced by the service as well as the concept. Thanks to the same control system, every employee can operate every machine - from the C 32 U to the C 400 V," explains Gmeiner. Also, he can be sure of being able to field whatever challenge may come: "We don't know what kind of order will be placed tomorrow. With Hermle machines, there's no way that we might be caught unprepared."

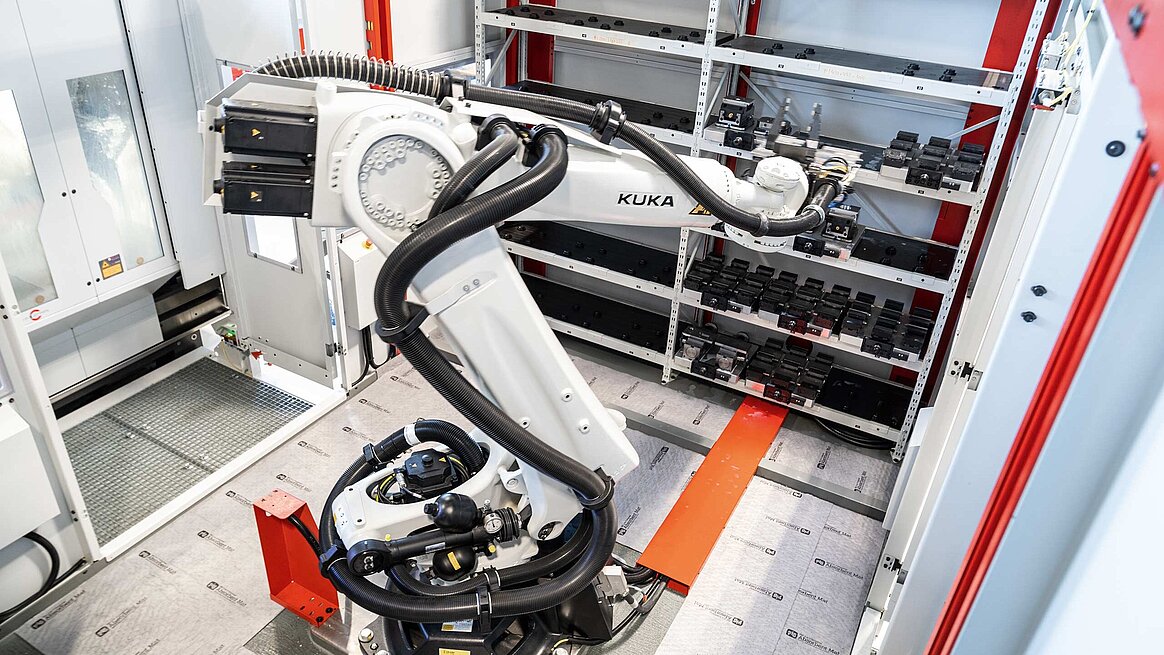

Standing in front of the latest investment – two C 32 Us connected with the RS 2 robot system – Manuel Gmeiner points to the black rails that are mounted beneath the hall ceiling and lead into the robot's working area. "When we invested in the robot plant from Hermle, we immediately thought about the connection to our Servus system," explains the CEO. The basic idea: A combination of milling machines, articulated robot and Servus system was the basis for fully automated manufacturing – from goods receiving to production to dispatch. The CEO underlines what this means: "So we only fully take notice of an order when it is already prepared for dispatch."

In practice, this requires the synchronization of many interfaces. Heron worked hand in hand with Hermle and the Soflex specialists to ensure that the ERP, the warehouse management software and the Soflex control system were seamlessly integrated. "That certainly took a lot of effort, but it went more smoothly than we expected," recalls Gmeiner. So the first stage of the project has been concluded successfully: If a customer orders an already known component, the ERP system takes care of the planning and material procurement. As soon as the material is booked in at goods receipt, Soflex is triggered. The software schedules the order according to capacity on the basis of running time, quantity and delivery date and orders the material just-in-time.

The Servus robotic carriers supply the raw material on a die – at a rate of 2 metres per second. The robot grips the die according to its coordinates, puts it into the storage location and sets up the required clamping device on the machine. The selection of the correct gripper and the clamping of the raw parts are also fully automated. When all parts are finished, a Servus picks up the die. The ERP system documents the current status in real time and releases the parts for shipment when they have passed the quality check. The precision, repeatability and dimensional accuracy of Hermle machining centres play an important role.