BUSINESS MODEL: FIVE-AXIS PRECISION MILLING!

C 50 U MT | C 30 U | C 40 U | Axis Tech

Czech company AXIS TECH s. r. o. is riding on a wave of sustained success thanks to its firm focus on the possibilities of five-axis/five-side complete/simultaneous machining using high-performance CNC machining centres from Hermle.

Established in 2010, and having progressed in just a few years from a standard supplier of mechanical parts to a widely respected high-end machining outsourcer for complex precision components, the Czech company AXIS TECH s. r. o., based in Opava-Katerinky, has a short yet highly successful history behind it. CTO Petr Michalek and CEO Petr Stencel turned their training into their when they incorporated their over 15 years' experience in NC and CNC machining into their own business, AXIS TECH s. r. o. Despite some teething problems, mainly due to the company's often inadequate machinery, switching to "the right high-performance CNC machining centres" proved the key to the success they were seeking. Petr Michalek explains how that happened: "We have lots of expertise in production, assembly and measurement jigs and fixtures and in component supply to the automotive, aircraft building and machinery manufacturing industries. We had the idea of utilising that expertise to make complex workpieces from a wide variety of different materials. So we procured some machines, but soon discovered that they were only of limited use in fulfilling our needs and in meeting the growing demands of our customers. As we had already had very good experience with Hermle machining centres, it seemed obvious to look to them for replacements of the machinery we had initially procured." It was during that phase that Martin Skukalek, one of the two field sales executives of Hermle Ceska Republika, got involved. He devoted lots of time to identify and understand the two start-up founders' philosophy and strategy, and ultimately came up with concrete proposals for a future-proof machinery portfolio.

-

[Translate to English:] Blick auf einen Teil der „Hermle-Parade“ mit zurzeit neun CNC-5-Achsen- Hochleistungs-Bearbeitungszentren unterschiedlicher Bau- und Leistungsgrößen der C-Baureihe -

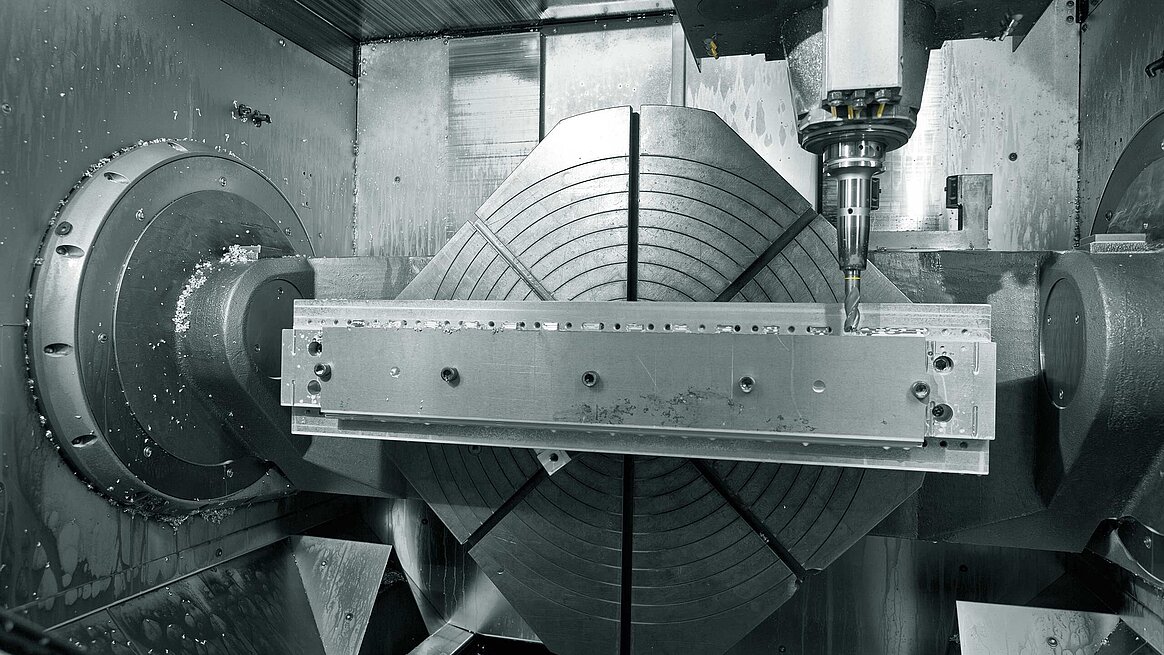

The working area of the C 30 U with the 540 x 540 mm NC swivelling rotary table; the maximum traverse/working range of 650 x 600 x 500 mm (X, Y, Z) and the collision circle-free swivel/rotation range permit complete fabrication of large-scale workpieces -

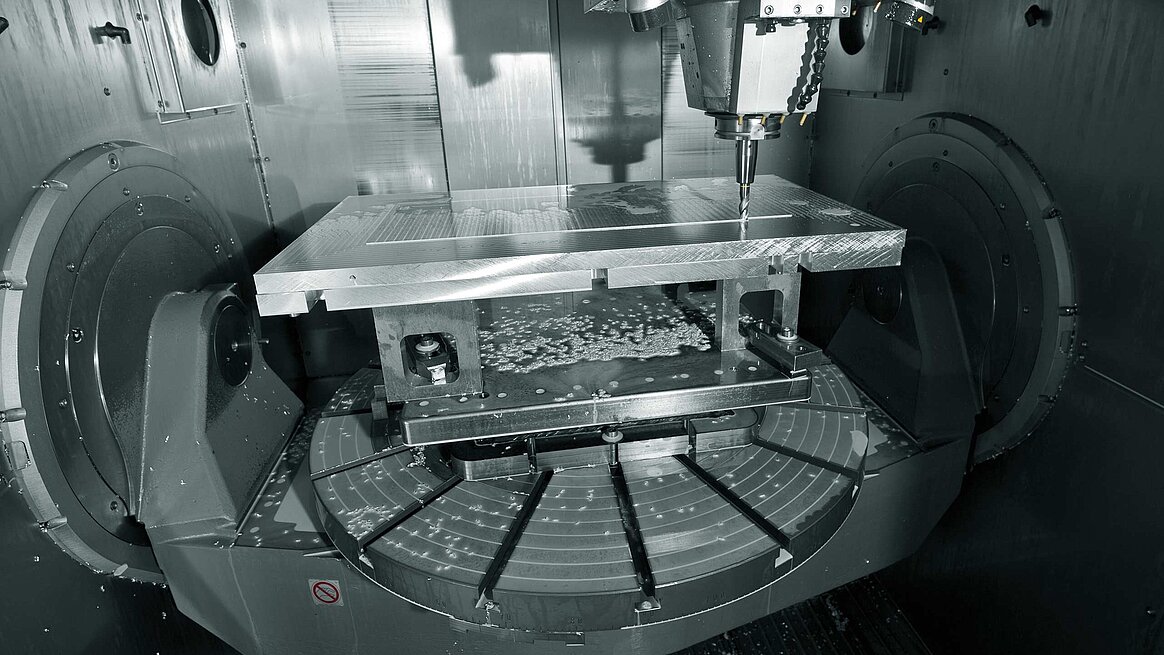

The working area of the C 50 U MT dynamic with turning function and the 1000 mm diameter NC swivelling rotary table; the high accuracy of Hermle machining centres enables complete machining of extremely large workpieces with supreme plane precision -

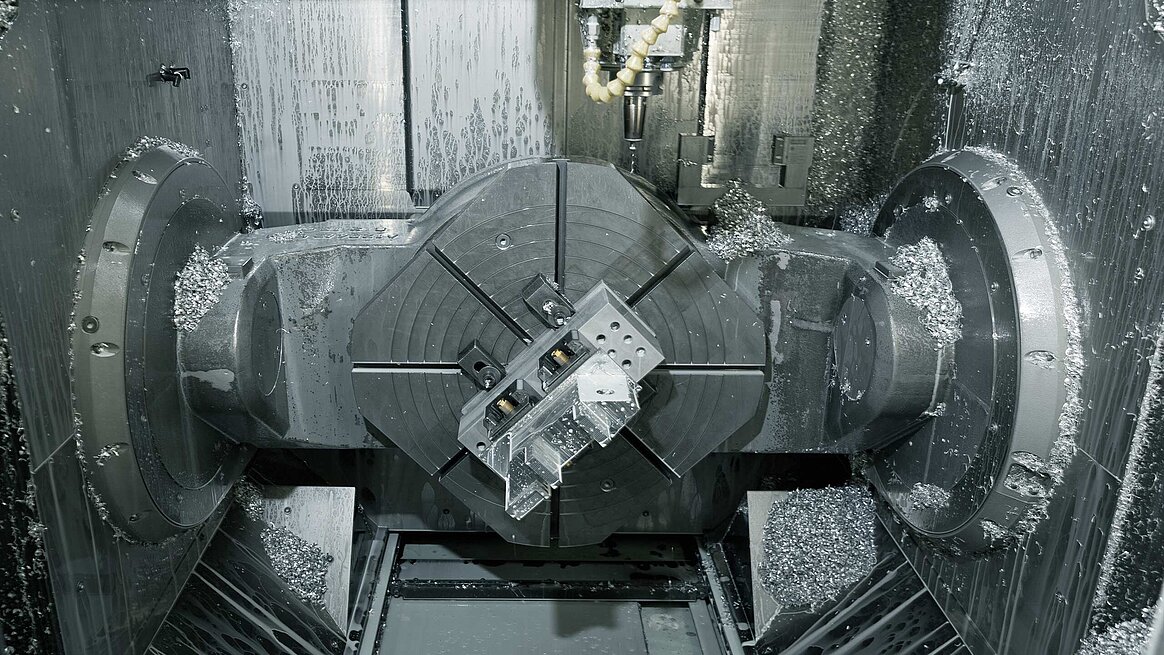

The working area of the C 40 U with the 700 x 700 mm diameter NC swivelling rotary table for five-axis/five-side complete/simultaneous machining of technically demanding workpieces

A ground-breaking investment in five-axis high tech

The proposals he made were gradually translated into machining reality, so that the business currently operates nine Hermle high-performance CNC machining centres, with another to follow by the end of this year. In keeping with the strategy – and of course in line with customer demands for high-precision complete machining of complex, increasingly functionally integrated, components – the milling and complete machining machinery portfolio today comprises a mix of C-series machining centres: C 40 U, C 30 U, C 42 U, C 50 U MT, C 400 and C 22 U. There are already three medium-sized C 30 U machining centres in operation, providing adequate capacity to serve that segment. With its mix incorporating almost all sizes and capacities of the C-series, AXIS TECH s. r. o. covers a wide range of potential component sizes, and with the C 50 U MT (with turning functionality) it is also able to manufacture components in specific sizes and weights in a single fixing by milling and turning. Starting from the smallest machine, the C 22 U high-performance five-axis CNC machining centre featuring an working range of 450 x 600 x 330 mm (X, Y, Z), and including the biggest, the C 50 U MT high-performance five-axis CNC machining centre featuring an working range of 1000 x 1100 x 750 mm (X, Y, Z), with maximum loading weights of their respective NC swivelling rotary tables (320 mm diameter on the C 22 U up to 1000 mm diameter on the C 50 U MT) and interchangeable pallets from 300 to 2000 kg, AXIS TECH offers its customers complete precision machining ranging from miniature mechatronics to large-scale integral components for aircraft or components and base plates for jigs and fixtures.

Machining centre mix optimally meeting customers' needs

The practical experts Petr Michalek and Petr Stencel took a similarly adept approach with regard to the configuration of their machinery. The machines all in principle feature the same specification levels, though the spindle speeds (e.g. C 50 U MT 12000 rpm; C 400 15000 rpm; C 30 U/C 40 U/C 42 U/C 22 U 18000 rpm) are configured to machine any materials occurring in practice (aluminium, steel, tool steel, difficult to machine steels, titanium). Hermle's Martin Skukalek comments: "Implementing the same machine design and operator control concept across all sizes, together with unified control systems, offers the major advantage that all staff trained on the machines can work very flexibly on any machine. The staff often don't even know which machine they are going to be operating when they come to work at the start of a shift. This means, depending on capacity requirements and the scope of complete machining work, it is possible to run a single order on one or more machines, thereby greatly reducing throughput times and so enabling very fast delivery to the customer. All AXIS TECH machines run in three-shift operation under operator control. In some cases, and depending on the complexity of the machining task and the workpiece runtimes, individual operators also control multiple machines, with up to five operators then being responsible for the nine machining centres." The reason why AXIS TECH is not intending to upgrade to a higher level of automation, such as for workpiece loading and unloading, in the foreseeable future is quite apparent when one considers the structure of the company's individual orders in more detail. Firstly, it specialises in machining a range of lot sizes from single components to small to medium-sized lots of a few hundred pieces. Secondly, the business sees itself as a technology leader in five-axis/five-side complete/simultaneous machining of highly demanding workpieces, and does not get involved in mass production.

Precision component manufacture 24/7

Petr Stencel concludes: "The scale of our business with a staff of 45 skilled personnel, our machinery portfolio and our measuring equipment means we are ideally set up to handle the fabrication and machining of technically demanding components. They include in particular components for aircraft building and the aerospace industry, as well as prototypes, sample series and jigs and fixtures for the automotive industry and its suppliers. We are able to produce in a highly flexible way, in line with specific needs, round the clock, seven days a week. Machining times range from maybe five minutes to five hours, so we are able to operate faster in operator-controlled mode than in automated mode – not least with regard to set-up and handling. We are not about volume production, but rather about utilising our expertise and knowledge. With our current portfolio of nine Hermle high-performance five-axis CNC machining centres – shortly to be joined by an additional C 22 U model to boost our capacity – we are the state-wide market leader in five-axis machining, and are committed to high tech from Hermle as a means of safeguarding our future competitiveness."