C 32 U | TVB | Graphite processing

Murnau can do more than art: Whereas "The Blue Rider" caused a stir in 1912, today it is TVB that shows off its capabilities with an offering that is unique throughout Europe. The family-owned company based in the Upper Bavarian market community on the Staffelsee packages and sells graphite blanks, mills complex electrodes for electric-discharge machining and produces the holders for them. When performing the challenging task of machining the porous material, the specialist relies on Hermle: two automated 5-axis milling centres are used exclusively to machine the black blocks while a C 32 U including a robot is responsible for metal machining.

With photovoltaics on the roof and a liquid-gas-powered combined heat and power unit – Andreas Rauchenberger spent yesterday thinking about tomorrow and is reaping the benefits today. It all began with a gentle hissing at the back of the hall: a leaky compressed air hose. "That is money that we have to earn in addition to the calculated machine hours", says the Managing Director of TVB GmbH. However, sealing hoses and using more efficient LED lighting was not enough for him: "We also use the waste heat from our Hermle machines. In the summer, we pipe the warm exhaust air into the cellar through our heat exchanger, in winter, we use it to heat the halls directly". Stefan Bux from HPV Hermle Vertriebs GmbH knows that more is possible: "In the meantime, there are water-to-water heat exchangers, for example, for switch cabinets, spindles and swivelling rotary tables, which must also be kept cool after all". This will definitely be the next step although Rauchenberger is not ready to take it just yet because the financial outlay would not justify the conversion.

"We are not yet self-sufficient", says Rauchenberger, turning his attention to the benefits of solar cells. However, that's not what he is referring to: The managing director does not see himself as a climate activist but believes strongly that everyone can contribute to climate protection – and the little things also count. Armed with this mindset, TVB managed to meet the standards of the greenhouse gas protocol for a climate-conscious company in 2022/2023.

In the black

TVB GmbH is a family-owned company that has specialised in graphite machining. It all began in 1994 with electric discharge wire cutting. "My father offered electric-discharge wire cutting and machining services and at the same time sold the machines that stood in the showroom. He believed it was important to have the technology that he sold in his own company and to understand it", says Andreas Rauchenberger. After completing his training, the last thing the qualified industrial mechanic wanted was to work at his parent’s company. This plan was thwarted by a plea for assistance from his father due to a shortage of staff: in 2009, he helped out as a CAD/CAM programmer, familiarising himself with the material and taking on more and more responsibility. He was also the driving force behind the specialisation in graphite given that the polycrystalline material had long since replaced copper as the electrode material for the electric-discharge machining of injection moulds. "Graphite is cheaper, easier to machine, can be purchased quickly and is thermally stable", says Rauchenberger, listing the advantages. He pushed for investment in new machining centres and automation – his father granted his wish. "Once you make your own decisions, for example, about a new machine or other processes, you are completely involved in the family business", adds Rauchenberger. The entire company was signed over to him in 2019.

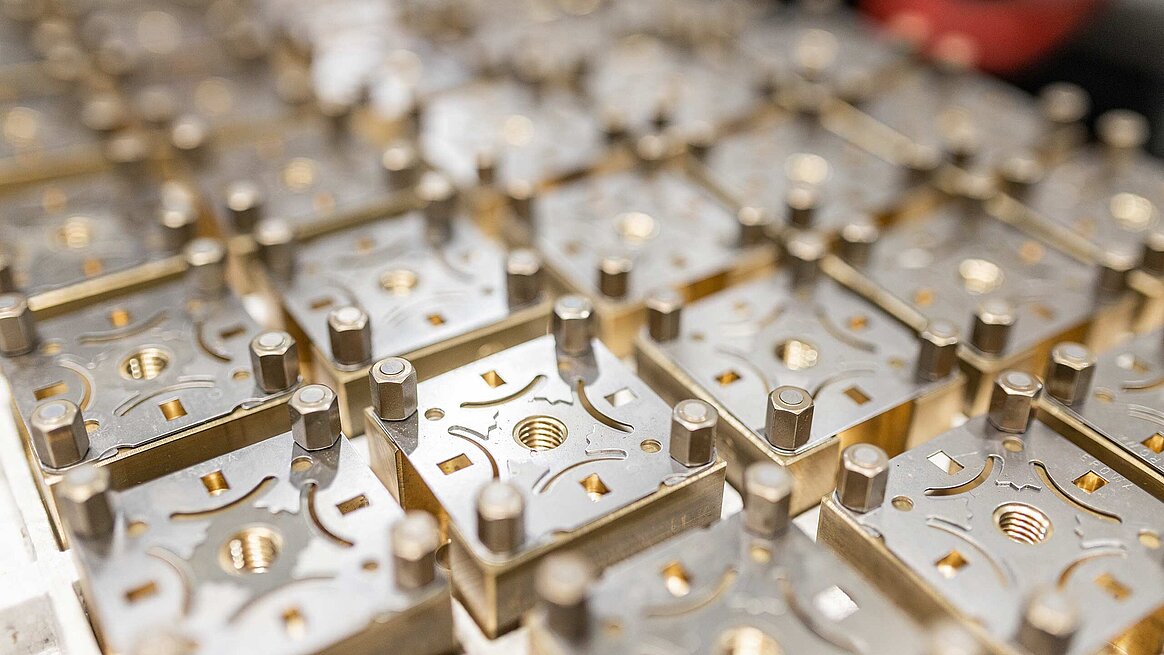

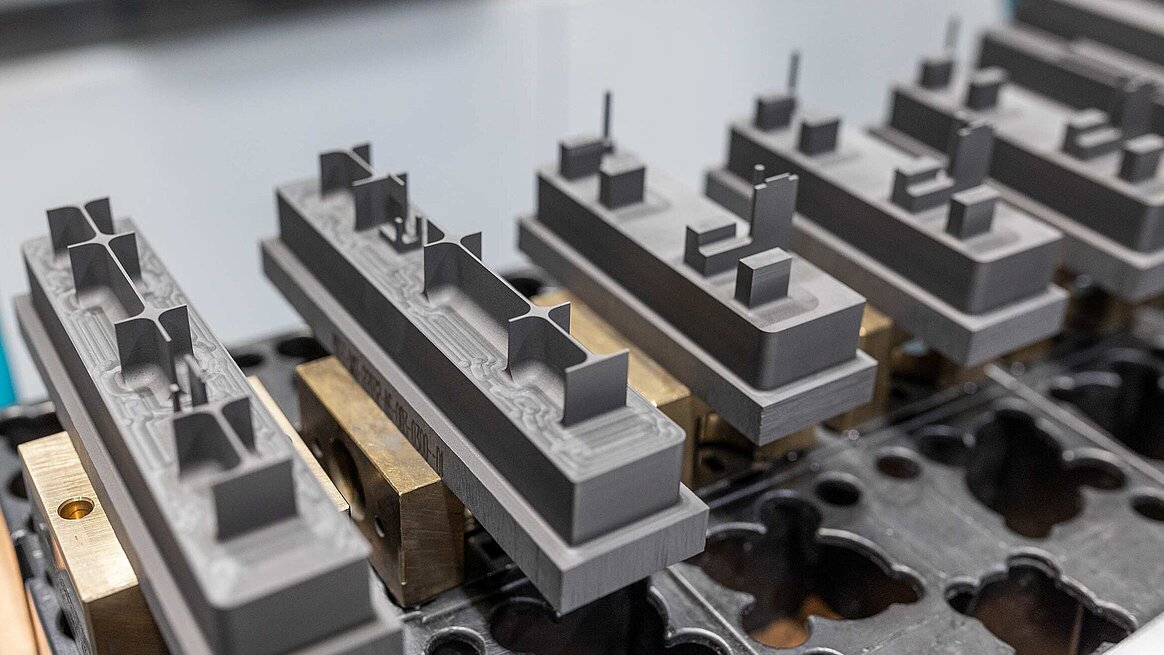

Today, TVB supplies everything related to the black blocks: from graphite blanks with a 24-hour delivery service to graphite semi-finished products and electrodes all the way to compatible clamping systems in the form of milled brass or aluminium holders. Rauchenberger is noticing a strong trend for outsourcing – whether as a result of staff shortages or because for some companies, it’s not worth investing in a machine specifically for machining graphite. "We have some customers that source everything from us: they purchase blanks and clamping systems and even use us as an extension to their own workbench when they have too much to do". As a result, TVB with its 17 employees now converts some 300 tons of graphite each year and produces approximately 30,000 electrodes.

Automated 5-axis machines

In 2015, TVB entered the world of automated 5-axis machining with the C 22 U and the IH 30 handling system from Maschinenfabrik Berthold Hermle AG. "We work in a one-shift system. To ensure that the machine would pay for itself and run without supervision, we had to introduce automation", was Rauchenberger’s view at the time. He made the right call: just one year later, the system was so well utilised that he ordered a second identical machine in Gosheim. That was because he believed that 24/7 operation was not ideal. The tightly-packed schedule with regard to deadlines leaves little space for servicing work. "It makes more sense to run two machines at 60-percent capacity utilisation instead. As a service provider, it is important to be there if the customer calls. We can only play this type of fire-fighting game if we have flexible capacities", says Rauchenberger.

He has been aware of Hermle since his days as an apprentice. He appreciates the company’s down-to-earth approach, the expertise of its employees and the service they provide, which he describes as unrivalled. However, the real reason he chose a milling centre from Gosheim is different: "The traverse range and the machine concept are fantastic. The working area below the machine tapers into a funnel shape, which enables optimum extraction of the fine dust created during the milling process", explains Rauchenberger. TVB purchased its own graphite extractor system and a covering cap to minimise the amount of graphite that can escape into the surroundings – or enter into the machine from outside.

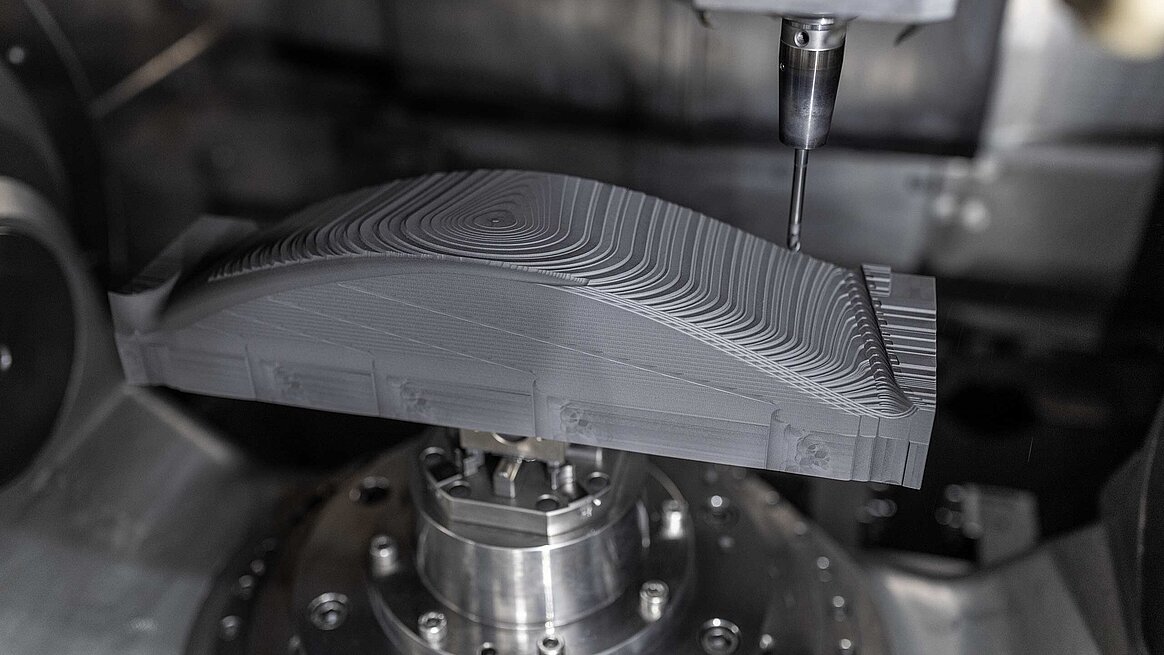

Why is this important? Graphite contains bonded granules with an atomic structure similar to that of diamond. No milling tool is capable of splitting these bonded granules. Instead, the goal is to tear them free from this bond – for which feed and speed play a key role. This separation process creates fine dust that can damage the machine in the long term. "For this reason, we use sealing air to seal all our guideways", adds the managing director. Hermle also fitted special rubber seals. The spindle with its maximum speed of 42,000 revolutions per minute is also the ideal design for machining graphite.

The crux of the crystals

It takes in-depth expertise to machine graphite. That's because the polycrystalline structure of the porous material varies from one manufacturer to another. "Some produce graphite that is slightly harder and more brittle. Others inject gas during the production process that makes it softer and easier to mill", explains Rauchenberger. The challenge with machining is to choose the right measurement to ensure that nothing breaks off. If the speed is too high and the feed too slow, the blade simply rubs against the ultra-strong granules. This results in poor surface quality and excessive wear on the tool.

The machine spends between five minutes and 36 hours milling an electrode. Throughout the process, it must master complex geometries while maintaining absolute dimensional accuracy. "We manufacture in the range of plus/minus one-hundredth of a millimetre. However, if we produce ten identical electrodes, they should ideally be identical when they emerge from the machine", explains Rauchenberger. Only in this way can he guarantee that the parts of a pirate ship join together securely later on, that shampoo bottles can close reliably or that the blades in a shaver can easily be replaced.

The most unusual application benefits Rauchenberger’s understanding of sustainability: a painting company uses the extracted graphite dust as an additive to its paint. This enables it to apply an electric current to the wall in order to combat mould. Likewise, off-cuts from the blanks are recycled for use in steel production.