C 50 U | RS 3 | Connova AG | Mold making & assemblies

The high-tech country Switzerland is always good for surprises! This can be seen, for example, in the car industry which literally does not exist for the Swiss citizens. Nonetheless, there are prominent and numerous ancillary suppliers in Switzerland in this branch (and in others) who are more than just so-called extended workbenches, but rather creative-innovative technology and service partners. One very good example here is the company Connova AG in 5612 Villmergen. Founded in 1983, and initially active in the areas of segment models and mould making for casting industry products, Connova AG has developed from a tool making company to an international specialist, and is in high demand for components and subassemblies for high-performance fibre-composite materials. They are experts throughout the process and value chain, from the idea to documented quality materials, components and delivery. The company slogan "new ways in composites" describes the future oriented possibilities that the use of specifically developed high-performance fibre composites can make available to industries and final customers. Light constructions and material and/or component economising lead to more efficiency in aviation, transport logistics and automotive/vehicle technology, can increase performance and precision by providing higher dynamic efficiency in production and robotics, or can contribute to completely new solutions in design, functional integration and functionality itself.

Invariably connected Composites and CNC machining

Jon Andri Jörg, CEO of Connova AG, on the service spectrum of the employees of this specialist team, numbering now around 59: "We see ourselves as a partner who accompanies customer needs in composites throughout the entire process: engineering, selection of material, CNC manufacturing of models, moulds and tools and CNC machining of the laminated components, right up to maintenance and repair of the tools and components. We have great expertise in selecting and determining of materials such as carbon, GFK, Kevlar or natural fibres and possess the ability and know-how for all manufacturing and machining processes. Particularly mechanical machining is of great importance in a time of great developments in the use of special composite components. It is therefore a decisive advantage for us to be able to prove expert knowledge, from CNC expertise to manufacturing of moulds and tools, including, particularly relevant today, 3 to 5 axis machining of composite components. Despite the fact that we have a particular special status, we have to produce economically, in order to remain in competition for our customers." This becomes clear if we consider – in accordance with the longer model cycles in the car industry – that manufacturing contracts for composite components can mean production of several thousand pieces over several years, produced and delivered in batches, in accordance with JIT criteria. For this reason, Connova AG invested 15 months ago in a flexible manufacturing system from Maschinenfabrik Berthold Hermle AG, D-78559 Gosheim. The acquisition was preceded by a detailed evaluation process with test machining, at the end of which Hermle emerged the clear winner. In addition to reproducible machining precision and dynamics in multi-axis complete machining, expertise in system solutions and high performance in direct service were convincing aspects.

Composite components (families) precisely and efficiently machined

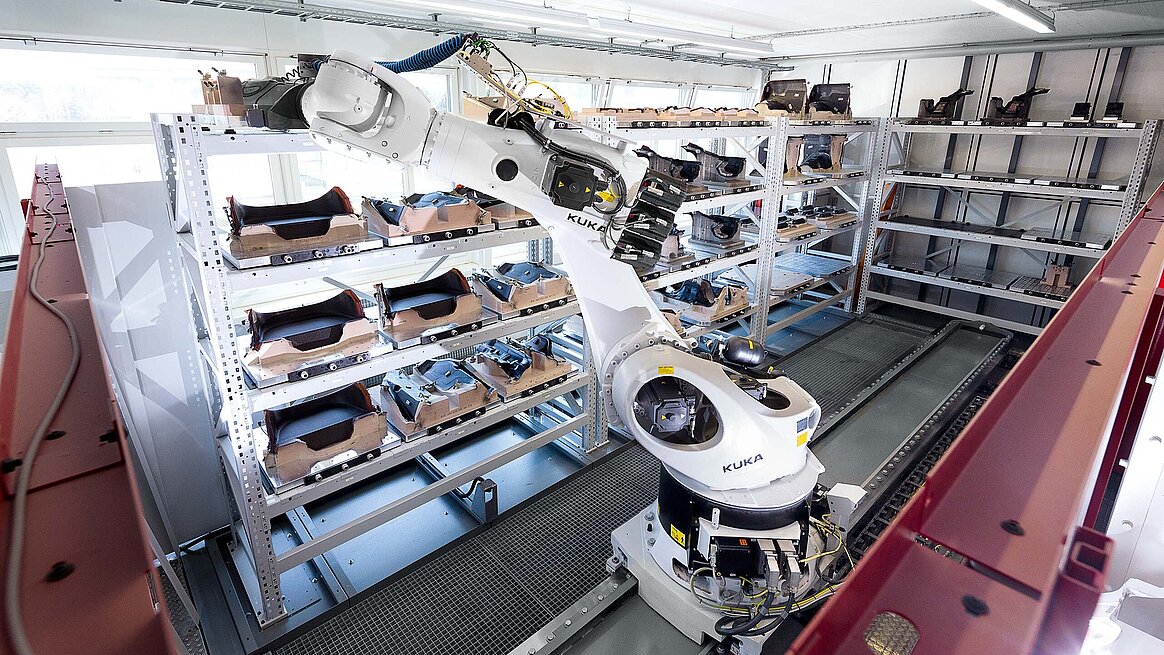

The flexible manufacturing systems from Hermle are conceptualised on a modular basis. They consist of one or several 5-axis CNC high performance machining centres, one or more workpiece/pallet set-up stations and one or more pallets/workpieces or additional tools. The automatic milling system installed at Connova AG consists of a 5 axis CNC high-power machining centre C 50 U, a robot system RS3 with linear additional axis, a pallet/workpiece setup station and four rack units to hold a total of 43 workpiece-pallets (33 pcs 800 x 800 x 540 mm and 10 pcs 1000 x 1000 x 540 mm). The Hermle machining centre C 50 U was selected because it has the largest working area of X = 1000 x Y = 1100 x Z = 700 mm and therefore covers the majority of workpieces that have to be machined. The machine is equipped with an NC rotary table of diameter 1150 mm, a main spindle of 18000 min-1, a HSK-A63 tool holding fixture, a standard tool magazine with 60 receptacles, an automatic cabin door, touch probe, tool breakage monitoring and the Heidenhain iTNC 530 HSCI controlling system. For holding the workpiece pallets, a zero-point clamping system was installed. The robot has the task of transporting the pallets from the setup station to one of the racks and then transporting it from there into the machine, or picking it up from a pallet there and putting it into temporary storage in the rack unit or handing it onto the setup station. Due to the fact that composite components (families) generally require more milling work and less drilling work, the 60 compartments in the standard tool magazine of the C 50 U are completely sufficient to be able to carry out 5 axis complete machining on five sides of a workpiece.

Exact positioning of the tool helps to avoid fraying etc.

Following a relatively short training period, the workers and the supervisor of CNC manufacturing at Connova AG, Philipp Folghera, were using the flexible manufacturing system, optionally, in a manned one-shift operation, or unmanned in a second shift, as well as in unmanned weekend manufacturing. In this regard, he explains: "The typical manufacturing batch for us lies at between 1 and 20 pieces but sometimes it goes up as high as 150. The flexible manufacturing system of Hermle contains between 30 and 40 extremely different tasks or extremely different workpieces which we process fully automatically, for example by all around engraving or milling of holes and gaps. The concept of the machining centre's C 50 U with 3 axes in the tool and two axes in the workpiece is ideal for composite machining, because the contours or milling tools, which depending on the form are often very long and jut out, always remain at a 90° angle to the laminated surface due to the 5 axis settings. In this way, and by using tools designed for the materials at hand, delamination and fraying is avoided from the very beginning and we can produce quality workpiece for workpiece." In the practice, this means that more demanding shorter pieces can be processed during the day and longer or more complex pieces at night or at the weekend, which, of course, occurs without cooling lubricant or, at most, with minimum quantity lubrication – this dispenses with any need for an ICS high-pressure device, which would otherwise be usual.