Flexible, 5-axis manufacturing cell for close-tolerance, unattended machining

C 22 U | Reliance Precision Limited

"The Hermle C 22 U machining centre is so precise that it prompted us to question the results we were getting from our existing shopfloor co-ordinate measuring machines. It led to the purchase of two new Zeiss Duramax CMMs – one for milled components and another for turned parts." (Kenny Marsden, Reliance Precision).

The company has operated three five-axis vertical machining centres for several years, but wanted to upgrade this area of production to meet customers' demands for ever higher precision. Alex Greenhalgh, Estimating Manager, commented, "The flexibility and high level of spindle utilisation possible on the HermleC 22 U were prime reasons for selecting it. We wanted to increase productivity while reducing manufacturing costs, which the automation equipment enables by allowing extended periods of minimally manned machining." The company was already very impressed with the precision and reliability of a 4-axis machine from Hermle installed in 2013 for the production of a tightly toleranced part for a customer in the aerospace industry. In addition, the support offered by Geo Kingsbury (www.geokingsbury.com) with regard to the installation, commissioning, user support and training had been exemplary, and an excellent working relationship had developed between the two companies. These factors combined played a considerable role in the selection of the latest machines.

-

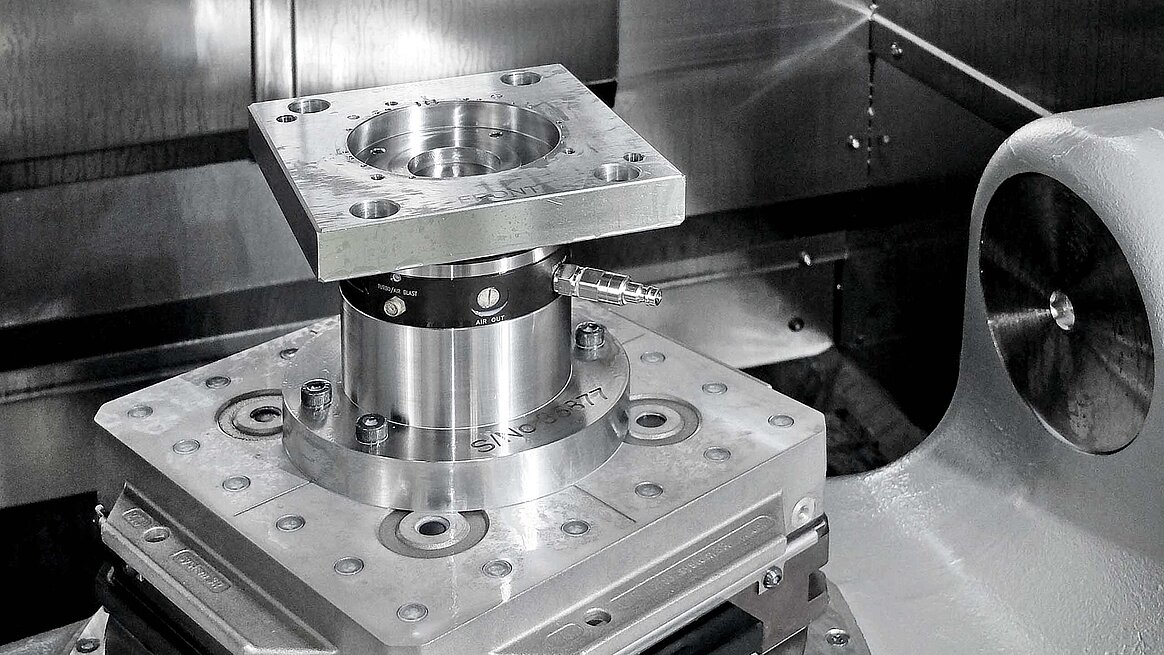

The 5-axis trunnion / rotary table arrangement of the C 22 U. -

The working area monitor positioned above the machine’s Heidenhain control system.

The 5-axis swivelling rotary table of the C 22 U

Reliance Precision's milling department team leader, Kenny Marsden, said: "Even though the C 22 U has been producing for only a few months, its accuracy is already evident. This has been proved by the on-machine probing, which verifies that tolerances have been achieved."

He added that manufacturing processes on the Hermle are ‘right first time' and remain within tolerance from first- to last-off, allowing the machine to be run largely unsupervised. Most of the five-axis machining at the factory in Huddersfield, UK, relates to prismatic components, where access to multiple sides of the workpiece with a high degree of accuracy is the primary requirement. It ensures that the tool can machine the component more efficiently in fewer operations, without the need for costly fixturing. For example, complex aerospace parts in titanium and stainless steel frequently require bores to be accurate to within 5 µm and true dimensional positions to be within 10 µm, in addition to a 5 µm tolerance for squareness and parallelism.

The time savings are enormous. In one instance, an aluminium housing that used to take up to an hour to clock into position on another machining centre takes just 5 minutes to set up on the C 22 U. The cost savings on work-holding are yet another benefit.

Reliance Precision is so impressed with the successful Hermle installation to date that it has recently decided to order a third machine. Kenny Marsden said, "Hermle offers the kind of features that you only get with the very best machines."