Standardization, high-quality machine investment creates long-term scalable production.

Birmingham, AL (Oct. 15, 2024) - Robert and Dell Smith started in the manufacturing industry as kids, working with their father at his part-time machine shop in Tuscaloosa – about 50 miles from the current Birmingham location. In the late 1980’s, Robert helped take the business to full-time operations, where they first experienced 5-axis and mill turn technology, primarily for the automotive and defense industries. The Smiths recognized the need for standard operations – whether tooling, controls or systematic procedures – which led to an exponential growth of over 100 team members. In 2015, they sold the company and six years later, they started Smith & Co. in Birmingham, AL..

“In April of [2021], we had an opportunity to start with a blank sheet of paper. And basically, build a company the way we wanted to,” said Robert Smith, CEO of Smith & Co. “Everything we chose, building what we have here today, was based on years of know-how and the lessons learned.”

With 40 years of experience and fostered relationships, the Smiths leaned into a systematic, automated approach to the new company.

They first met with HERMLE at IMTS 2018. After decades of research and investigation, the brothers waited for the right opportunity to invest, and when they did, they went all in.

“We heard such good things about the HERMLE platforms, the machines, the repeatability, the accuracy – basically, the stability of the machine,” said Robert. “With HERMLE machines, it is an investment… but we look at is an investment for long-term.”

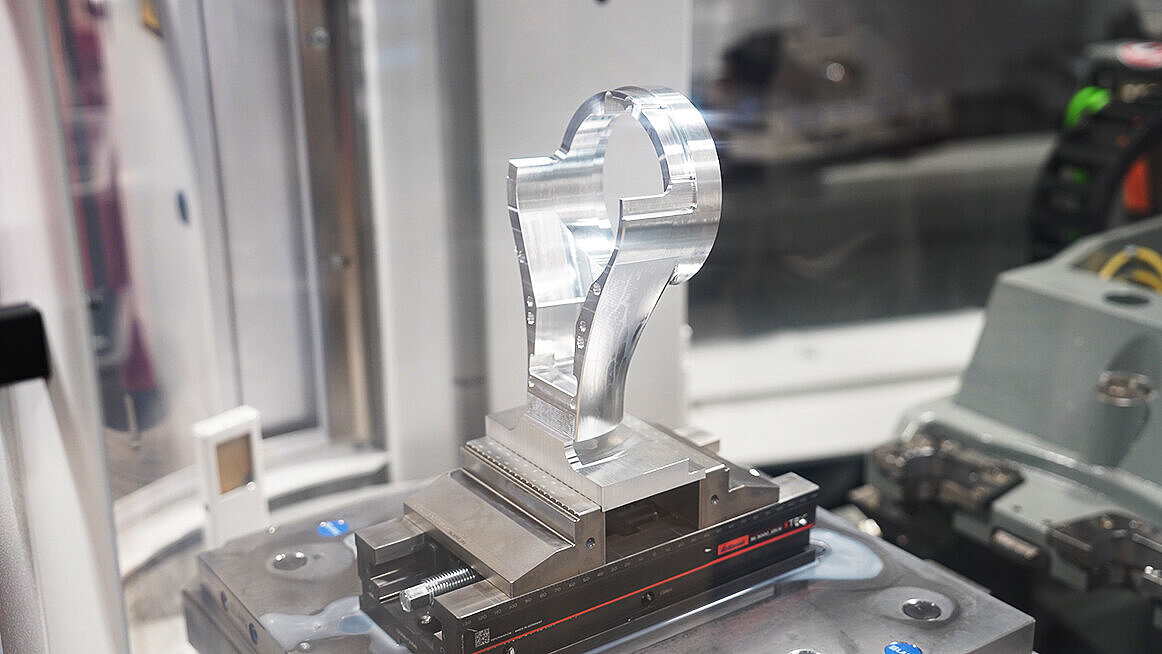

Making parts from aluminum, titanium, alloy and more – the Smiths separated their service from competitors by harnessing processes and utilizing high-quality machines and automation technology to their maximum capabilities.

-

HERMLE USA Regional Sales Manager, Stephan Schmitt with Smith & Co. team. -

Smith & Co. manufactures components for the defense medical and commercial industries using all 5-axis machines and automation. -

Mechanical Engineer, Jake Smith and Chief Operating Officer Dell Smith inspect work on the HERMLE C 400. -

The Smith & Co. facility in Birmingham, AL, running entirely HERMLE 5-axis machines and automation. -

CNC Machinist Brandon Webster programs machining cycle on Smith & Co.‘s C 400 5-axis machine.

Predictable Quality with HERMLE Technology

From probing and tooling to programming and automated pallet handling, they leaned into HERMLE technology - so much so, his team will not purchase other machines. “We have predictable quality at this point. We’ve had zero problems with service or maintenance,” said Dell Smith, Chief Operating Officer at Smith & Co. “They operate, they communicate, pretty much flawlessly. That’ll be the only milling machines we purchase – will just be HERMLE.”

Because HERMLE machines can hold incredibly tight tolerances and their automation can run seamlessly, according to Smith, the team ends up working a lot less hours, resulting in minimal to no turnover. “I think they’re a very straight-forward, simple, easy machine to operate – to be honest with you, compared to some other machines I’ve ran in the past,” said Stryker Moffat, Engineer at Smith & Co.. “I think the way someone worded it was ‘do one thing but do it well.’” Service support, ease of operation, asset sustainability, vertical integration, and machine design were a few reasons Dell mentioned why HERMLE was the first and only choice for the young company.

“The HERMLE machines are basically scaled machines, so they know what they’re doing,” said Dell. “Everything is done in a timely manner. We’ve experienced no challenges communicating and getting the answers we need – be it applications or service. It’s just a non-struggle there.”

Following their initial investment in 2021, Smith & Co. has since expanded operations, currently running two C 250 machines, two C 400 machines, and one C 400 with the HS flex pallet handling automation technology.

Smith said that easy installation and integration were largely due to HERMLE’s consolidated machine and technology offerings – only providing 5-axis solutions.

Three years later, the brothers are now producing complex machine parts for the defense, medical and commercial industries, 24 hours a day, 5-7 days a week – often turning away work incompatible with impressive systematic operations.

So, what’s next for Smith & Co?

The foundation built over the last three years – a strong team, an impeccable system of processes, and reliable machine technology – put Smith & Co. in a position to scale high quality production for current and future customers.

“Our machines have created a really good environment that promotes lean operation,” said Dell. “We’re able to output the same quality on the same type of machines and its powerful, and its scalable.”

To request more information about the HERMLE C 400 or about Smith & Co.’s investment in HERMLE, email jwilliamson@hermleusa.net.