From sawing to 3D complete machining

Employees can use the C 60 U for traverse paths of X-Y-Z = 1,200-1,300-900 mm as well as a table load of up to 2,500 kg and for high-precision machining of components, including deephole drilling. It is equipped with the swivelling rotary table measuring 1,350 x 1,100 mm in diameter and standard equipment featuring a 70-piece tool magazine and the workpiece holder HSK-A 63. The tool spindle has a top speed of 18,000 rpm, an 80 bar high-pressure cooling lubricant unit. Furthermore, the system offers electrical heat compensation, sealing air for the glass scales, tool measurement and breakage monitoring, touch probes and a Heidenhain iTNC 530 HSCI control unit.

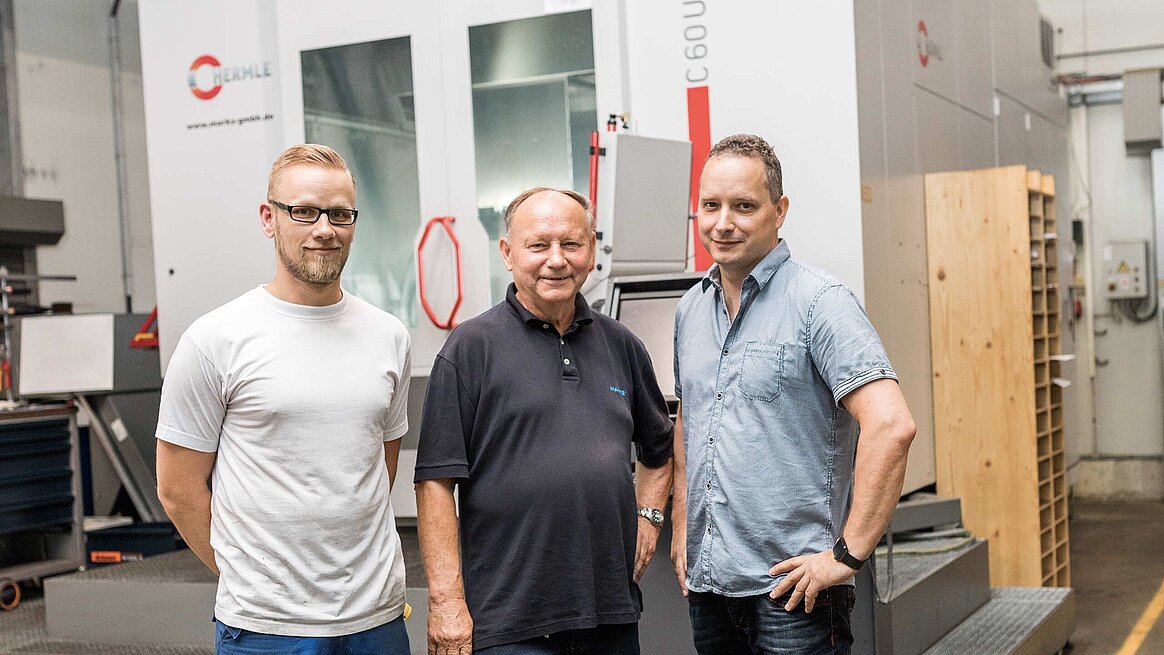

“In order to meet our demands for more comprehensive delivery capability and extensive adherence to delivery dates, we rely on the maximum performance and availability of our machinery,” says Lothar Marks. “When we finally met up with Hermle in 2006 through customer contacts at a trade show, it was the beginning of a fruitful cooperation based on trust. How effective and efficient the four machining centres actually are can be seen from the fact that only two qualified employees are needed per shift for their operation and support.