Technology based manufacturing services

C 42 U | Prodrive Technologies | Electrical engineering and electromechanics

"Ready to use products" or contract manufacture as part solutions or complete solutions from a single source – the middle-sized Dutch company Prodrive Technologies has made a name for itself within a short space of time and works on contract for high-tech companies from diverse areas of industry as a partner in development and subassembly/device manufacture. The young company, around 20 years old, obviously ticks differently from most of the classical on-demand manufacturers and sees itself as a "vertical integrator". Just about all relevant disciplines of technology necessary for autonomous manufacture are represented among the 750 employees of the Prodrive Group. In this way, Prodrive Technologies distinguishes itself strongly from specialised service providers who concentrate on only one or few technology types. The live and practical philosophy "Ready-to-use Products" places high demands on those working in the mechanical manufacturing departments: to be able to react quickly and flexibly, with technical know-how and highest quality, to meet customer wishes and the needs of in-house production. The general essence is: "We are completely autonomous in the areas of electronics and mechanics with regard to development and manufacture. Of course the same is also true for software, so that we are a single source supplier for our customers, with optimum coordination from development to JIT delivery logistics. This means high demands on technology, processes and capacity, and of course all process steps must run economically. For this reason, whenever possible and sensible, we integrate high levels of process integration and automation in order to utilise the available technological systems to their fullest maximum in single-shift operation and in automated nightshift operation."

Going for Gold with five axes or moving straight in at the highest level

There is no need to worry about moving straight into investment in high technology at the highest level – although that means procurement of machines and tools as well as, in particular, recruiting and training of professional personnel – as the following example shows: the highly automated manufacture of mechanical components on 5 axis machining centres. Although the initial manufacturing-technical focus of Prodrive Technologies, in electronics and electromechanics, was based in the quickly growing works in Eindhoven and Son, it became clear in time that the delivery of mechanical components from external suppliers disturbed the in-house product-technical workflow and had a detrimental effect on deliveries to the final customer. Consequently, the strategic decision was made to move the mechanical manufacture in-house. On the lookout for powerful equipment, Prodrive Technologies came into contact with Geert Cox of Hermle Nederland B.V. and presented a list of requirements on the basis of the possible component sizes needed. Among other products, favoured were 5 axis complete/simultaneous machining; a manned single shift unit, as well as nightshift manufacturing of individual components and small batches with workpieces of diverse running/machining times; and finally, step-by-step implementation with the option of post hoc automation. After a detailed analysis and consultancy, the decision was made at Prodrive Technologies to "Go for Gold". Subsequently a 5 axis high-power machining centre of Type C 42 U with additional tool magazine ZM 160 was procured from Maschinenfabrik Berthold Hermle AG, D-78559 Gosheim. The first 5 axis machining centre was the foundation stone for the successive founding and extension of the Department for manufacture of flat and cubic mechanical parts, for example complex cooling elements for electronic subassemblies as well as highly filigree components for functionally integrated mechatronic subassemblies.

-

From left to right, Sietze de Jong, Group Leader Operations at Prodrive Technologies, in the middle Geert Cox, Managing Director Herme-Nederland B.V. and Chris van Helmond machine operator at Prodrive Technologies, in the Son works -

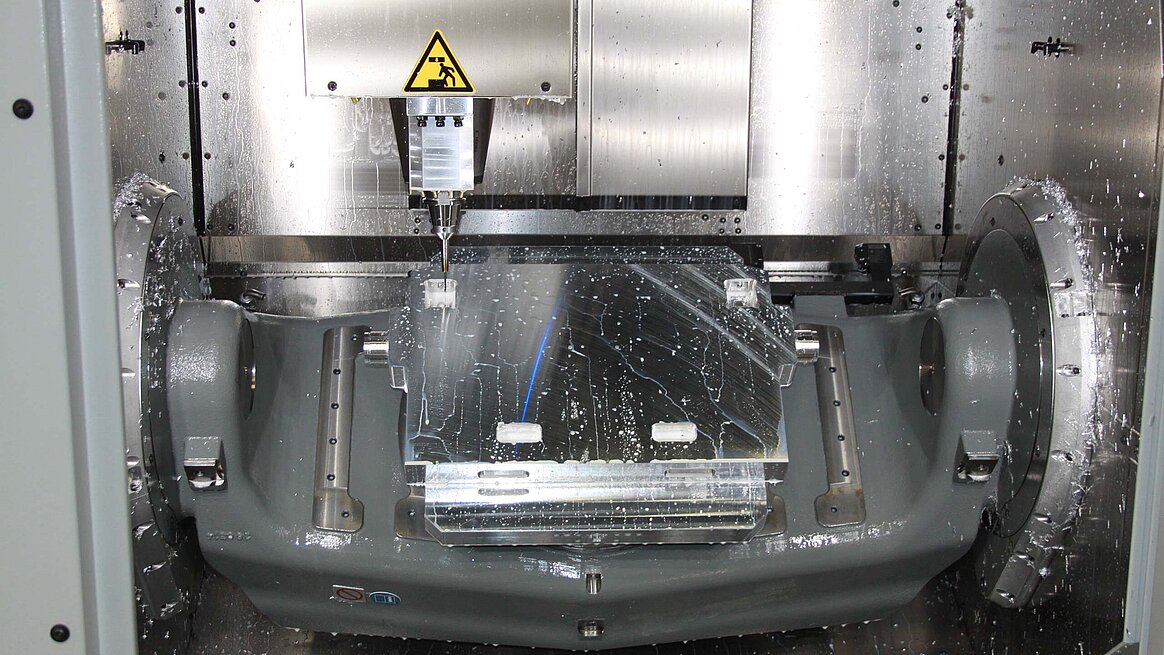

The large working area of the machining centre C 42 U for complete machining of high precision cooling base plates as well as filigree precision components for mechatronic subassemblies -

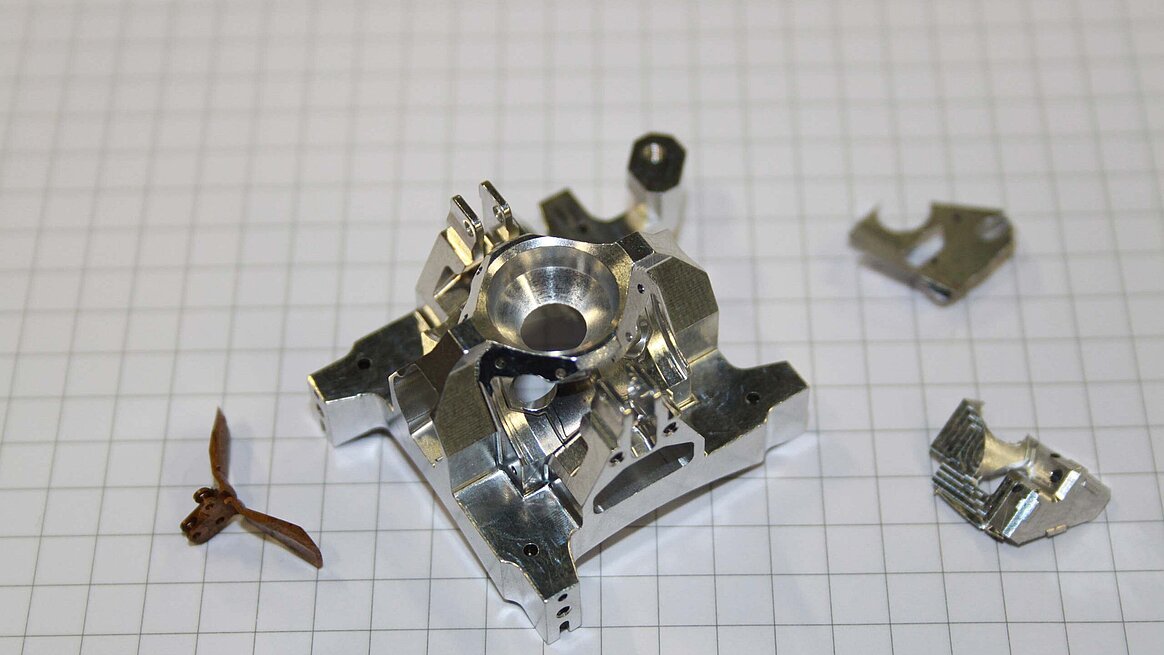

A complex 5 axis high precision component for mechatronic subassemblies and devices

The Hermle machining centres, of construction size C 42 U, cover the spectrum of the workpieces

In order to be able to ensure the desired flexibility, in addition to the necessary capacity, Prodrive Technologies invested, in quick succession, in four further 5 axis high-power machining centres of type C 42 U, so that, now today, there are five of these "productivity, quality and flexibility pushers" in operation. Currently the new milling department at Prodrive Technologies consists of three machining centres C 42 U, connected per robot system RS 2, and two C 42 U machining centres as stand-alone systems. The machining centre C 42 U, which was procured first of all, was followed by a second and by the robot system RS 2. A third machining centre C 42 U was then integrated in this system. Furthermore, Prodrive Technologies procured both of the aforementioned stand-alone C 42 U machines, which are used predominantly for manned, highly flexible, quickly needed "priority manufacturing" of individual parts and for smaller series. The C 42 U machining centres which are connected per robot system and workpiece magazine are used preferably for JIT oriented small and middle batch manufacturing "around the clock" as well as for communal manufacturing of entire component families with high fitting-accuracy requirements and component compatibility. All machining centres C 42 Us are equipped with main spindles with a maximum speed of 18000 min-1, an NC swivelling rotary table with torque drive and a diameter of 440 mm, the workpiece holder HSK-A 63, ICS high-pressure, 80 bar, coolant feeding as well as a zero-point workpiece clamping system. In addition, each of the two C 42 U machining centres, which are set up as stand-alone systems, have an additional magazine ZM 160 with a further 160 tools. This means that a total of more than 200 tools are available, including the basis tool magazines which have 42 receptacles per stand-alone machine, all of which guarantees interruption free complete machining of the most complex precision components or entire workpiece families.

An equal partnership from the beginning

Furthermore, our responsible partners at Prodrive Technologies are very happy with the partnership with Hermle and with the support provided in all phases during the introduction and the further development of the 5 axis technology on the premises of Prodrive Technologies: "After examining the possible component sizes, we chose the C 42 U, which proved to be the right choice, because we can now manufacture base plates for cooling subassemblies just as precisely as we can produce small parts with edge dimensions of just a few millimetres. Usually, the number of pieces required is between 10 and 500, but we often also need to manufacture prototypes and individual parts which, naturally, are required very quickly. We therefore find the open concept of the system very accommodating: designed for highly flexible use as a manufacturing system, consisting of the connected triple system with three machining centres and two stand-alone systems. It is particularly useful because we have between 20 and 50 new workpieces to machine each week. By setting up our own mechanical manufacturing unit on the basis of the 5 axis technology from Hermle, we are now in a position to offer our customers optimum solutions and to implement these quickly. Additionally, we were able to use mechanical precision-component manufacturing as a way of closing the final gap, so that we are now autonomous in all relevant areas of production and are independently able to produce Ready-to-use products.