C52 | C 42 | BRAVO-TECH BVBA | Contract manufacturing

BRAVO-TECH knows how to manufacture complex geometries and perfect surfaces. Customer feedback and full order books confirm this fact and have led the Belgian subcontractor to regularly expand its machinery with Hermle 5-axis machining centres. It appreciates the high level of precision that basically does away with the need for manual reworking.

Whoever has the chance to chat to Bram Vergote soon realises: He is a tech-savvy adrenaline junkie. He loves motorcycle racing and is not afraid to take risks – both in off-road terrain and in business. He discovered his fascination for engines at the age of eleven, when he was allowed to dismantle and investigate his mother’s no longer used Citroen 2CV. An interest in mopeds and go-karts soon followed. “My firm also started life with motorcycles and engines,” says Vergote, founder and managing director of BRAVO-TECH bvba. He left school in 2001 and bought his first manually operated milling machine to machine parts for his motorcycle in 2004. Six months later, he invested in his first CNC machine and began producing parts for other people. In the evenings and at weekends, he devoted his time to his own business, while his days were still spent working for a steam boiler manufacturer. "I did that for two years, before handing in my notice and never returning – not as a member of staff anyway," adds Vergote. He is still in contact with his former boss and occasionally produces small parts for the company.

BRAVO-TECH is now a successful contractor based in the Belgian town of Oudenaarde. The company mills, deburrs and polishes moulds for hard-top cases, blades and turbine wheels for compressors and pumps, as well as engine components such as camshafts and crankshafts. The most unusual order to date: Over 70 door handles ordered by an Arab prince for his palace in Oman. “Because of the many details, one latch took 27 hours on the machine,” Vergote recalls. When one of its major customers ended its contract during the COVID-19 pandemic, the Belgian company moved into new sectors and now also manufactures camera and lens housings and carriers for satellites. Vergote particularly enjoys complex assignments and believes there is a solution to every task. He relies on his know-how and experience as well as on his machinery, which enables him to produce geometries and surfaces to the required quality and precision. And he is not afraid to invest in order to further develop his company. Vergote therefore entered the world of 5-axis technology in 2011 and bought his first machining centre, a C 30 U, from Maschinenfabrik Berthold Hermle AG in 2012 – he trusted a friend’s recommendation at the time and has been delighted with its performance and service ever since.

Lots of space for precision

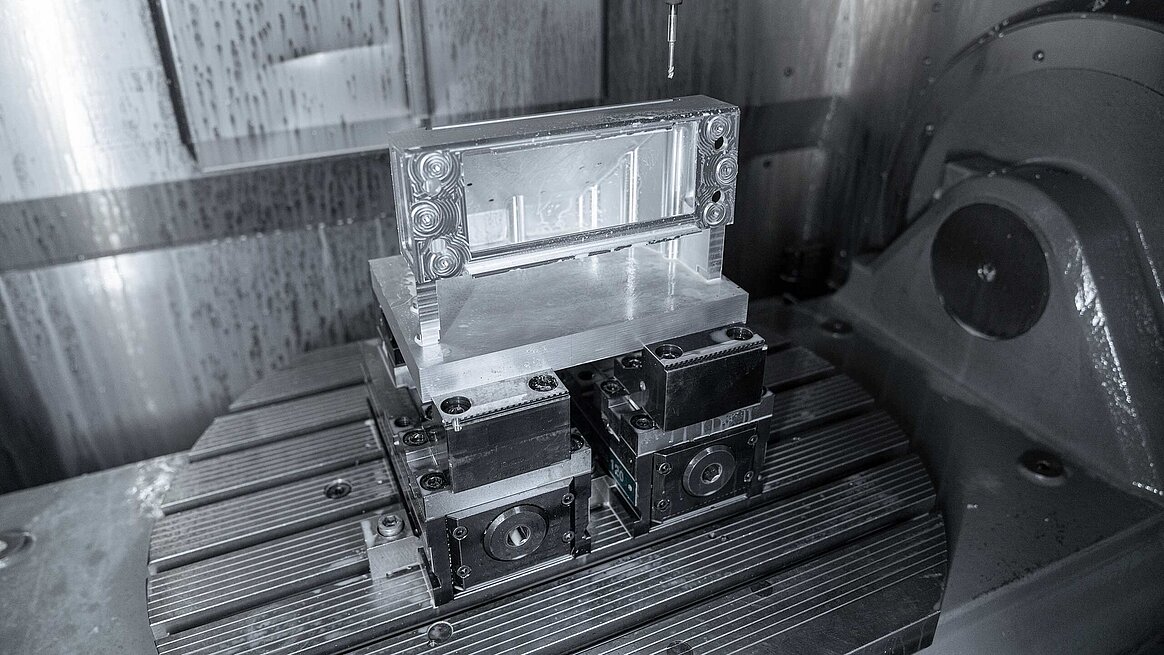

In the meantime, he has regularly expanded his machinery with milling centres from Gosheim: In 2013, he bought a C 400 U, followed by a C 12 U and a C 52 U in 2015. A C 42 U and another C 400 U have been hard at work in Oudenaarde since 2017 and 2018 respectively. In August 2021, he ordered his seventh machine, a second C 52 U. He uses it to machine the same orders as on the version purchased in 2015, which he needed at the time for one reason only: One of his now most important customers, a case manufacturer, was demanding greater quality in less time. How did this come about? Cooperation with the luggage manufacturer began with simpler and smaller tool components. Over time, the components grew in size and complexity, as did the demands of the client. “Before we had the C 52 U, it took us eight weeks to machine a complete mould. That was too long for the client. What we needed was a machining centre that would save us time when reworking moulds and offer enough space for the moulds of all case sizes,” explains Vergote. Further, the machine had to be able to create the finest details in the surface. Vergote leaves the room and soon returns with the shell of a case: The thin lines that later give the case its unique visual texture can only be seen from close up. “What looks like a textile structure is in fact milled into the surface of the mould by the Hermle machine. In the past, we had to rework all the moulds by hand. Today, depending on the size of the tool, the C 52 U needs just ten days and operates very precisely. We have been able to do away with a lot of manual work and achieve a significantly better surface quality,” explains the 42-year-old entrepreneur.

But you also need the space if you want to invest on a regular basis: In 2015, BRAVO-TECH had to relocate. Initially, Vergote purchased only part of the current company complex. Over time, he expanded the production space by purchasing and renting the adjacent buildings. Since September 2022, the company has occupied the entire building complex. The fact that Vergote can continue to expand is basically down to his flexibility, know-how and willingness to take risks. Like many others, the company also faced a decline in orders during the COVID-19 crisis. Vergote made the most of the time and invested in software, training and machines. “I wanted to return more professionally proficient, skilled and efficient after the COVID-19 crisis,” Vergote explains. Looking back, he admits he might have taken too many risks and invested too much at a time when orders were in very short supply. Nobody knew how long the situation was going to last. “But it was also an adrenaline rush and it definitely paid off in the end,” admits the Belgian businessman.