Technical Data

Dimensions

-

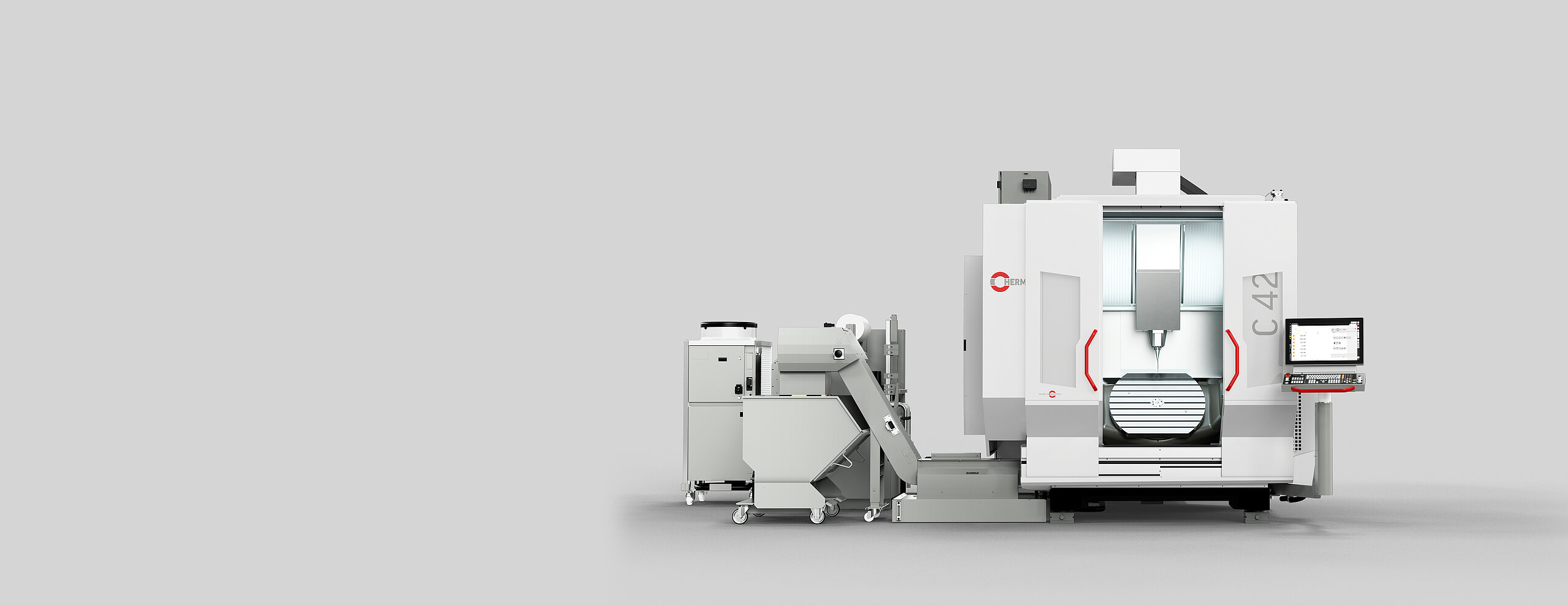

Traverse path: 800 x 800 x 550 mm

-

Body: Ø 800 / H 560 mm

-

Collision circle: Ø 990 mm

-

Vertical table clearance: max. 700 mm

Facts

-

Rotational speed: 15000/16000/20000/25000/42000 1/min

-

Rapid traverse linear X-Y-Z : 45 (60)–45 (60)–40 (60) m/min.

-

Swivelling rotary table: Ø 800 x 630 mm

-

Max. table loading: 1400 kg

Applications

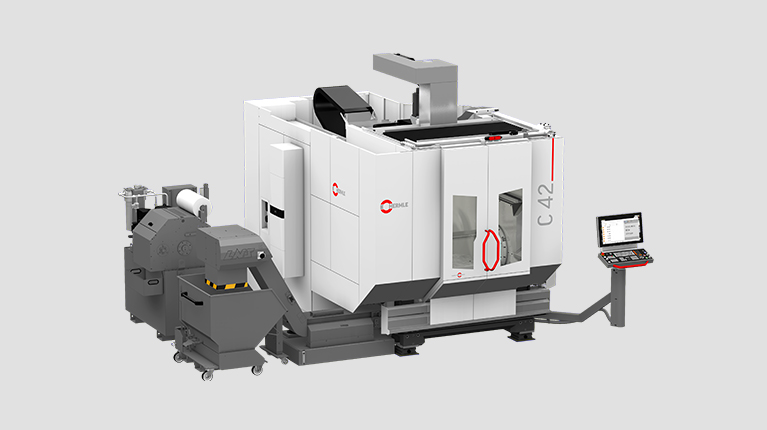

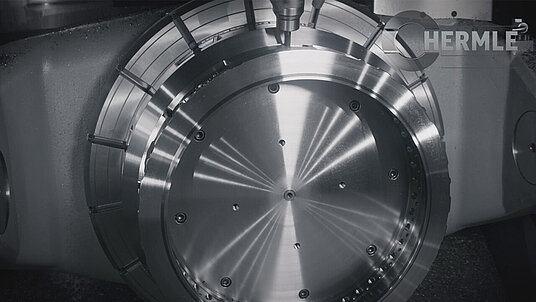

C 42 U MT | Aircraft and aerospace industry | Engine housing

HERMLE C 42 U MT dynamic in 5-axis mill-turn version. Machining an engine housing in 1.2312 for the aircraft and aerospace industry

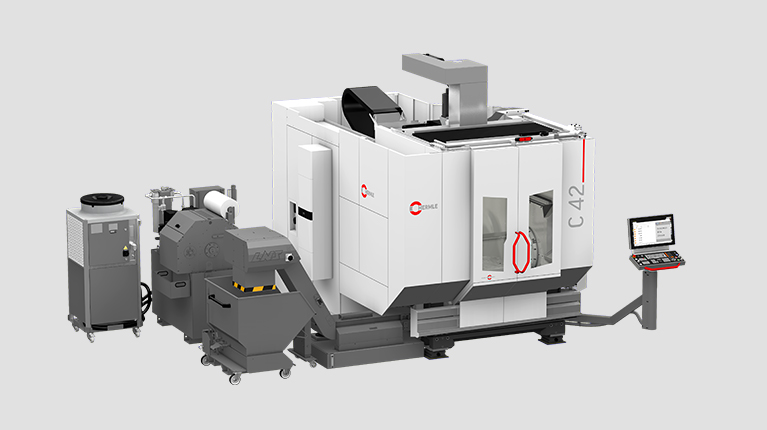

C 42 U MT | Aircraft and aerospace industry | Skiving/fir tree

HERMLE C 42 U MT dynamic in 5-axis mill-turn version. Machining a milled/turned part using skiving and fir-tree cutters in 1.1730 for the aircraft and aerospace industry

C 42 | Aircraft and aerospace industry | Pipe support

HERMLE C 42 U dynamic in 5-axis version, machining a pipe support in AlMg4.5Mn for the aircraft and aerospace industry, production of the outer mould using effective 5-axis roughing. Production of the deep cavities using 5-axis tubing.

User reports

Cooler thanks to copper in the core

S&S Werkzeugbau GmbH

Spritzgusstechnik

Tool and mold making

S&S Werkzeugbau manufactures complete injection moulds entirely in-house – from design through to the initial moulding. However, the mould makers make an exception in the case of a reliable cooling solution for narrow cross-sections: Hermle Maschinenbau uses metal-powder application technology (MPA) to integrate copper into mould cores, thereby optimising heat outflow in the injection moulding process.

Accurate to the nearest hair is not precise enough

SK Technology

Prototyping

SK TECHNOLOGY is formidable when it comes to precision. That’s the result of an awareness that minute subtleties are the difference between acceptance and rejection – and a stock of machinery that can withstand critical inspection down to the micrometre range. This is where Hermle succeeds. Six automated 5-axis machining centres allow the cutting expert to be really picky.

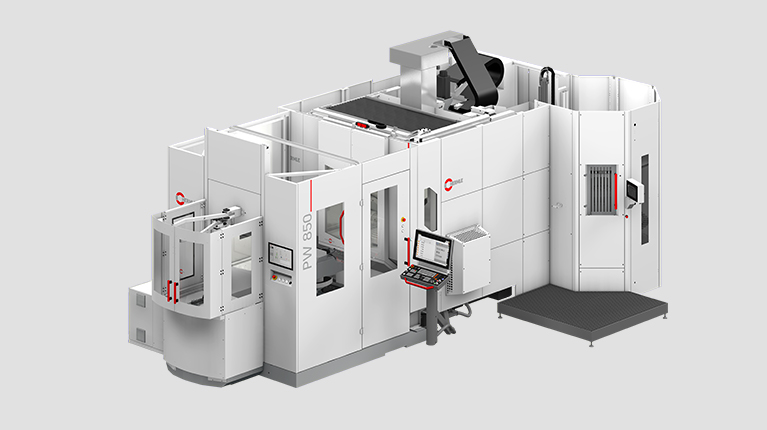

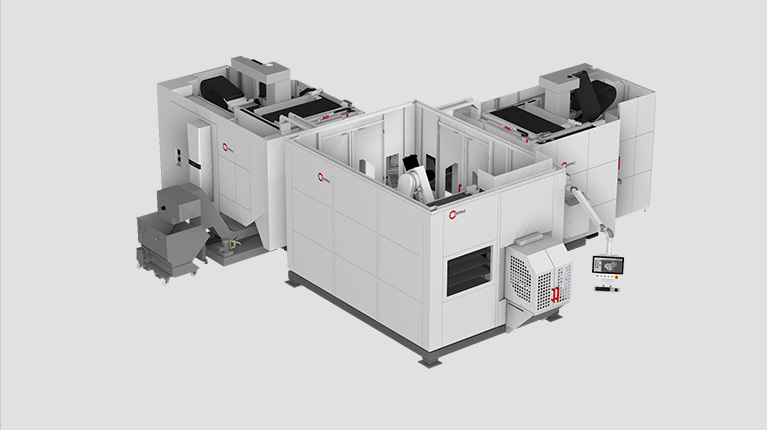

Duplicate machines at NMH

NMH GmbH

Contract manufacturing

Price, quality and delivery dates are what really interest his customers, explains NMH Managing Director Christian Bulander. More recently, one robot and two virtually identical Hermle 5-axis machining centres have been helping the specialist engineering company and contract manufacturer to meet these challenging demands efficiently.